Transparency is Both the Challenge & Opportunity for the Fashion Industry

The fashion industry is incredibly complex.

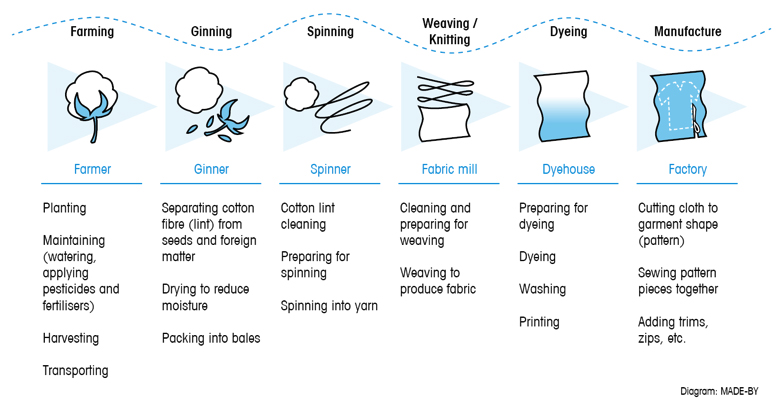

Fashion is a global network. From growing the cotton, weaving it into fabric, dyeing and finally sewing the garment together, each step is completed by a different group of people, in different regions and even countries. Some brands have over 500,000 different products on the market at once worldwide, thousands of factories associated with them, and millions of workers all having a hand in creating their products.

It is positive that the fashion industry is able to support the employment of so many people, in regions where opportunities can be limited. The challenge, however, is making sure that the livelihoods of these workers are protected, sometimes even above the accepted standards in that country, and that the environments in which materials are extracted and processed are not negatively impacted by these activities. Many brands have invested significant resources to evaluate and decrease these impacts, however numerous continue to struggle with achieving transparency of their supply chain in the first instance.

Why is supply chain transparency a challenge?

The strength of fashion brands is in providing consumers with finished products they want to purchase – it is not in growing cotton, mining tin, dyeing wool, or all other stages of production of fashion. Because of this, their supply chains are setup to primarily place orders directly with factories which produce their final products. Some brands do purchase key fabric or components to their products, however brands are towards the end of incredibly intricate networks of factories and workers. To achieve transparency, brands need to work backwards to identify these factories who have had a hand in producing the components used to create their products.

We lead projects with brands to uncover their supply chains. These projects are always an ongoing process of communicating the intent to suppliers. The focus is on building trust in that brands are not seeking to leapfrog over suppliers to secure better commercial deals with upstream suppliers, but rather, honest attempts at uncovering who made their clothes and how these were made. We have had some great successes in these projects, finding ways to decrease impacts quickly, connect brands to workers who they would’ve never been able to tell stories about otherwise (e.g., Mongolian goat herders), and build comprehensive pictures of their supply chains and their associated risks. In some cases, we find deceptive behaviour or suppliers being unwilling to share this information. The brands we work with then need to make a decision. Some have decided to make a stand that it is no longer acceptable to them to source from suppliers who do not share this information. Others are still trying to get this supply chain shift sold internally. However, in both cases, the important thing is that transparency is now a factor in sourcing, and is being discussed by both sustainability teams and commercial teams as the new basis for further impact reductions. Without having visibility to these suppliers, brands are unable to support impact reductions more upstream in the supply chain. Once visibility is established, we have seen impact reductions of all sizes, from investing in new machinery to simply adding nozzles to hoses to save resources.

A fundamental shift is coming

By 2050, the global population is expected to reach nine billion people – all of which will not only need clothes. Climate change has already began impacting harvests for materials like cotton worldwide, and is only expected to cause further supply disruptions in the coming years. Industrial pollution too has devastated environments, with 43% of rivers in China being unsuitable for human contact (not consumption – contact). Competition for resource is ever increasing with poor yields from harvests, and even with resources we take for granted such as the groundwater level in Bangladesh dropping by multiple metres every year, requiring factories and communities to continue drilling deeper and deeper to find water.

Legislation and international guidelines are also changing worldwide which means that companies will have full responsibility for the social and environmental impacts of their supply chain from start to finish. For some brands, this will be a catalyst for action. For others who have already invested in projects to identify and support suppliers, their first mover advantage has put them in a better position to comply with these legislations, but also have created some other potential benefits. A key high-street brand recently shared that their commitment to sourcing Better Cotton Initiative cotton for their products created a space to build trust with suppliers, get to know them better, and support them with their challenges.

Transparency as an opportunity

We must be aware that opening up an entire global industry cannot happen overnight. Instead we should celebrate some of the leaders who continually engage with their supply chains, and share with the world some of their findings (both positive and negative) and some of their stories.

Transparency will be the vehicle by which brands can identify their supply chain, engage with these suppliers and improve the environmental and social impacts associated with the production of their products. Sustainability engagement has moved far beyond a charitable exercise, it is becoming a critical business activity.

Transparency is set to be a game changer on supply chains and effective action can begin to make this a reality.

Stefanie Maurice, Principal Consultant, MADE-BY