When Ubuntu Made first came to Maai Mahiu, we found a community of children with special needs and their mothers being mistreated and secluded. The stigma and lack of understanding surrounding special needs in Kenya means extremely limited access to essential services such as education, affordable healthcare, physical rehabilitation, and vocational training. This leads to limited opportunities for social inclusion, many social and economic issues for their families, and ultimately limits their ability to live the life of dignity that they deserve. Ubuntu first created the Ubuntu Special Needs Centre (SNC) to combat this stigma and injustice by providing therapy, education, and vocational training to youth with special needs in Maai Mahiu. Caring for these children had been a full-time job for their mothers, so soon after enrolling their children in the SNC their Mums started a new conversation with the founders: “Now that our kids are out of the house, can you help us do something productive with our time?”

The answer was a fashion line, initially imagined to create jobs for these Mums. Today, those same women have formed into a sisterhood revered in the community: women who provide for their families, purchase land, and venture into their own successful entrepreneurial efforts. Which is why it’s not simply about creating jobs.

“Plenty of people have been given opportunity, but they don’t feel empowered,” explains Zane Wilemon. “There’s something magical about our culture and creating a job within that; it then empowers the whole community.”

This conviction is what led Ubuntu Made to design and launch the Afridrille. At the intersection of customization and sustainability, the Afridrille merges customer experience with genuine connection. Based on the popular espadrille style shoe, their version marries modern on-demand manufacturing technology to an artisanal production process. Customers can choose from an incredible array of styles, choosing from a range of canvas colors, printed patterns, pattern colors, and African kanga linings. There are over 23,000 different design options, so each pair represents the personality of the individual customer. That means that each pair must be made to order, not produced in bulk in advance.

The key to making this process work is technology and expertise provided by Zazzle, a Silicon Valley company that makes customizing anything a possibility. They’ve applied their cutting-edge technology to enhance the customer design process and have dedicated hundreds of hours of senior staff time to help Ubuntu develop the new product, in a collaboration that re-defines what true “corporate social responsibility” represents today.

“At Zazzle we’re thrilled to extend our platform and technologies to Makers who craft products with soul, made from the heart. And there’s perhaps no better example of this than the Ubuntu Mums,” explains Jeff Beaver, Zazzle co-founder and Chief Product Officer. “Through our partnership with Ubuntu we’ve learned that providing economic opportunity is exponentially more impactful, and sustainable, than handouts or charity. These Afridrilles are more than just awesome shoes, they are a celebration of the human spirit, and every single pair empowers these Mums, their special needs kids, and their larger community. What’s better than that?”

Crowdfunding the product launch via Kickstarter allows Ubuntu to build up production capabilities, expand the skillset of their ‘Maker Mums’, and perfect a complex operating process with the support of the Kickstarter community.

“Never underestimate the power of the entrepreneurial spirit and what can happen when people collaborate on something bigger than ourselves,” says Wilemon. “With the support of Zazzle and an eager crowdfunding audience, together we will scale up production and empower thousands of women and families in Kenya.”

At Ubuntu, empowerment means more than providing handouts or even a sustainable job. It means offering people a chance to create their own lives and livelihood. Ubuntu Made pays above-market wages to all of our employees – up to 4 times as much as they would have been able to find elsewhere in the community. We also provide health insurance to all our employees and their families, a rarity in Kenya where less than 20% have access.

The job skills our Mums learn and the money they earn empower them to buy homes – more than half of Ubuntu employees are homeowners compared to 1% nationwide. They are able to provide for their families, and sometimes start their own enterprises. They earn more than money; they earn respect in their community. Together, by providing disabled children with the healthcare and education they need, we empower them to realize their fullest potential.

That’s empowerment. That’s Ubuntu in action.

This week we are celebrating Fashion Revolution and the journeys of two women and acknowledge the barriers they have overcome. Nobody tells it better than the weavers themselves – they’re the true beating hearts of The Basket Room and the story behind each woven basket we sell. So we caught up with two members of the Kenyan weaving cooperative we work with: Peninah and Florence. Here’s what these talented craftswomen have to say about being working women in 2017, and the barriers they have overcome through basket weaving and working within a cooperative.

Peninah Munyao was born in 1978. She is married and has three sons aged 16, 11 and 4. As a housewife, she manages the household and also dabbles in farming and of course, basket weaving. Like so many of the weavers we work with, Peninah was taught to weave by her grandmother.

Florence Bernard is treasurer of the weaving cooperative Peninah works for, and was born in 1962. With five children aged between 38 and 23, Florence also runs a greengrocers’ as well as weaving baskets and travelling frequently to Nairobi to sell baskets. Florence has been weaving baskets since 2001 and was taught the craft as a child, by her mother.

What do you feel you have achieved as a working woman?

PENINAH: From basket weaving, I am able to meet the needs of my household: paying school fees, putting food on the table and buying clothes and other essentials, as well as having some money left over to save.

FLORENCE: I have been able to support my greengrocery and basket trading businesses from the money I make from basket weaving. I also use this income to support the needs of my family.

What challenges do you face as a working woman?

PENINAH: Sometimes it is difficult to source enough sisal fibre, since the plant is grown in a different region and it can take a while to arrive at our markets. Since I am also a mother and a housewife, my duties – primarily, taking care of my family – have to take precedence over weaving, which means that sometimes I cannot produce as many woven baskets as I would like to.

FLORENCE: Rain, although a massive blessing to farmers and food sellers, impedes basket weaving. When it does rain, weaving must stop so that the crops can be tended to. Likewise, drought also hinders basket production because again weaving must stop so that we can travel further afield than normal to find water.

Has work given you more independence?

PENINAH: Yes! Before I joined our weaving cooperative a few years ago, I used to rely on my husband for everything we needed at home. Back then, I felt I couldn’t even ask him for money for a new pair of shoes because there were just too many more important things for the home that we needed first. But when I started weaving with our cooperative, I had the means to not only help support the family, but also to surprise my husband with new things for him, like a new hat or a pair of trousers.

FLORENCE: I never travelled much before, but since we started selling the baskets in Nairobi, I’ve realised how much I enjoy travelling. I am now able to travel all over Kenya with my work, and sometimes I take my family with me. I also don’t have to rely solely on my husband’s income in running my household anymore.

Do you feel successful being part of a growing weaving cooperative?

PENINAH: Yes, I do! Not only because this is the best way to trade with buyers, but also because of the togetherness that comes from doing something you love with friends and people who can relate to and understand what you are going through.

FLORENCE: Yes. We usually contribute part of the sales of our baskets to our cooperative. These contributions have made it possible for us to purchase a piece of land where we intend to construct rental properties or a community centre. Group members can also take out loans from the savings we have.

Thank you to Peninah and Florence for sharing their stories with us. Peninah and Florence belong to the Kenyan weaving cooperatives that produce our popular Linear Fusion range of woven baskets and shoppers.

Carol is the Quality Control Supervisor at SOKO Kenya in the Rukinga Wildlife Sanctuary. She manages a team of 5 people, and her daily responsibility is to make sure that all of the factory’s production is up to standard. “I guess you could say I’m a perfectionist, “ says Carol, “at the factory I like to make sure everything is checked with great care and detail.”

Carol is from the Vihiga county in Western Kenya. After completing primary school she moved to Mombasa on the other side of the country in the hope of getting a high school education. Unfortunately her mother passed away a few months after she left. Carol’s grandmother looked after her siblings and cousins, but she could not afford the school fees. Carol found work as a cleaner for a local coastal family and sent money back to support her grandmother. In 2002 she met her husband and became pregnant with her first child. She was 16 years old. Without family around her to help to look after her baby, she was forced to quit her job while her husband supported the family with his income as a bajaj driver.

It was in 2009 that Carol’s prospect’s changed. She heard about SOKO Kenya and she applied for a job as a helper. Over the past six years, through hard work and an eagerness to learn, she has been promoted to a supervisor role. “Employment has not only empowered me but also it has motivated me in so many ways,” Carol says. “My dream is to become a designer.”

Last year Carol was awarded a scholarship to the UK, and she spent two months attending a pattern drafting and garment construction course. “I got to experience a life which is so different to what I am used to. I felt like the UK was a different world, and it made me wish that Kenya would one day be a developed country like that.”

“I attended other conferences, particularly about design, and it inspired me to start thinking out of the box. I found out that there are all different types of designers, even ones who design road signs! When I came back after two months I had so much knowledge to share with everyone, and endless stories to tell. My heart was filled with joy, my face full of smiles and a song of thanks to God for making this dream come true.”

The SOKO factory is based in an area which suffers from the lowest employment rates in Kenya. There are high rates of prostitution, HIV/AIDs and wildlife poaching. SOKO aims to empower women by providing employment and training in a safe and fair environment. Through this we hope to establish an ethical and sustainable workplace which will benefit the local people and the wildlife both now and for future generations.

On April 24th, 2013, 1,134 garment workers died when an eight-story building, named Rana Plaza, collapsed in Dhaka, Bangladesh. This event marked the beginning of Fashion Revolution Week (April 18-24). It is a time for us to honor garment workers, those who have died in all industrial tragedies in the garment industry, and those who are still suffering in the fashion supply chain today.

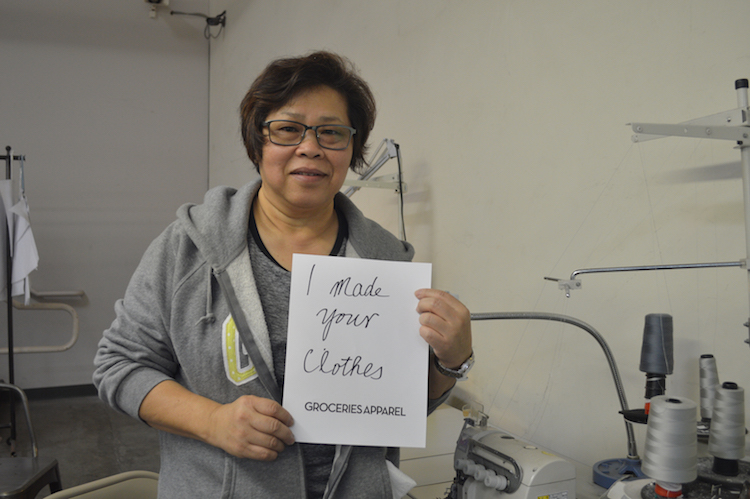

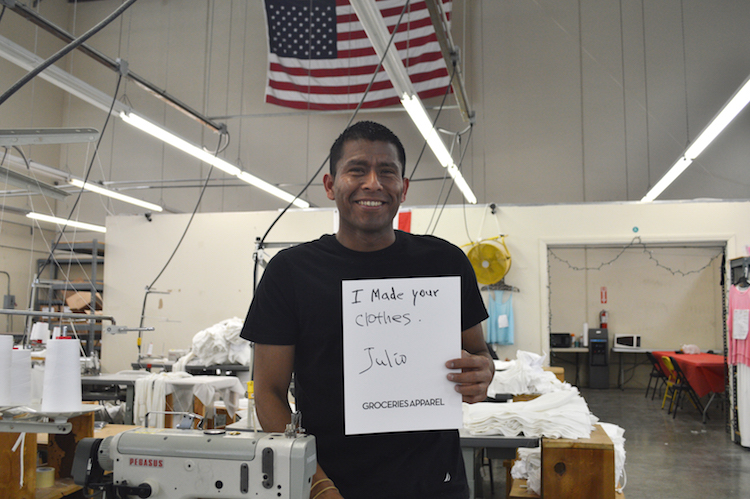

At Belvele, we are taking this opportunity to highlight fashion brands who are doing the right thing, by paying fair wages, providing safe working conditions, and treating their talented employees with the respect that they deserve. Although all of our vendors produce ethically, Groceries Apparel and Threads 4 Thought were nice enough to introduce us to some of the people who are making your clothes.

Groceries Apparel

Groceries Apparel operates its own factory in Los Angeles, taking responsibility for their impact on customers, employees, communities and the environment. In addition to ensuring ethical manufacturing, the company uses environmentally conscious materials, such as organic cotton and recycled polyester.

Linda is the pattern maker and a co-founding member of Groceries Apparel, who has been with them for over six years.

Julio is the sew team manager. He has been working at Groceries Apparel for five years.

Threads 4 Thought

Eric and Leigh, the company’s founders, personally travel around the world to find the best Fair-Trade facilities that share their values, and to build relationships with the owners, management, and workers. Their locations include Kenya, India, China, and Haiti. All garments are made with sustainable textiles, such as Organic Cotton, Lenzing Modal, and Recycled Polyester.

Jael works at Wildlife Works in Kenya, one of Threads 4 Thought’s Fair Trade Certified partners, which is located inside an 80K acre wildlife preserve.

Dorothy produces graphic tees and tanks for Threads 4 Thought at Wildlife Works, a carbon-neutral factory which is part of the REDD+ Project, which protects forests, wildlife, and communities in Kenya.

As Fashion Revolution Week approaches, we encourage you to find events near you, and to get involved with the slow fashion movement. Ask your favorite brands on social media, #whomademyclothes to encourage them to be transparent and let them know that you care about their supply chain. With each dollar we spend, we place a vote for the kind of world we want to live in.

Join us on 4/21 for a screening of The True Cost.

Margaret Mschai, a mother of two, makes her living by completing various tasks at the Wildlife Works eco-clothing factory, and is wholly grateful for it. Her tasks include trimming, folding and packaging the fabric and finished clothes.

“I love what I do mostly because it is an important part in the chain of events that creates unique outfits for export,” she says, adding, “We cannot all be machinists or designers. Someone has to trim the loose threads and fold the clothes so that they are presented neatly for the final consumer.”

As Margaret never had the chance to continue her education past primary school, she was therefore unable to accomplish her dream of becoming a nurse. Like countless girls growing up in rural Kenya during the 1970s, Margaret’s parents did not see the need to educate a female child. Upon completion of her primary school education, she was left with the options to either get married or begin working to sustain her everyday needs.

Against her parent’s wishes, Margaret chose to spend a term at the high school she had been admitted to. However, before she could take exams at the end of her term, she was sent back to her parents for money in order to pay her tuition fees. Sadly, she was unable to obtain the funds and was forced to leave school and abandon her hopes of becoming a nurse.

Unable to fulfill her ambitions, Margaret found herself moving from job to job until 2002 when she got news of the clothing factory near Maungu that was hiring.

“I had a strong conviction that this was the long-term opportunity I had been looking for when I heard about the Wildlife Works eco-clothing factory,” Margaret, who had learned a few basics of sewing through the years, recalled.

Unfortunately, the machines at Wildlife Works were electronic, as opposed to the manual ones she had been used to. Instead of the sewing job she had hoped for, Margaret was hired as a factory assistant. Among the first to be employed at Wildlife Works eco-factory, Margaret was unfortunately laid off in 2008 when the factory closed for a temporary three-year period. She describes these years as the hardest period of her life.

In developed countries, laid off employees are typically able to find a new job and move on with their lives. However, in a country like Kenya, where the unemployment rate has reached a staggering 40%, this is far from the reality. After the closing of the factory, Margaret learned first hand the hardships faced by those who have no job prospects in their area.

“I had a child to feed and no one was willing to employ somebody who had not gone past primary school- not even as a lowly paid house help,” she laments.

Luckily for Margaret, her husband was employed elsewhere and so they were able to survive on the little that he earned.

Fortunately, Daniel Munyao, the factory manager at Wildlife Works, re-employed Margaret and others when the factory resumed production in 2010. According to Daniel, Margaret is one of the most hardworking employees at the factory. Even when there are no orders being processed, she spends her time learning how to operate the electronic sewing machines.

“I love sewing and I hope that I will one day get a promotion to become a seamstress,” Margaret says.

With what she earns as an employee of Wildlife Works, Margaret hopes to start her own local fashion shop, selling imported second-hand clothes. Her enthusiasm is apparent as she speaks of her future ambitions.

While Margaret might not have completed her secondary school education, she has undoubtedly lived a life full of valuable lessons. One of these, which she would like to pass on, is to never give up on life, to learn to rise past your challenges and make the best out of every opportunity.

At Wildlife Works, we wish Margaret all the best for her employment, dreams and future aspirations.

Today Africa is a destination of second hand clothing. Kenya alone imports over 75 million piecess of second hand clothing and distributes not domestically but in the regional market of eastern and central Africa. This is really shameful that Africa in fact produces just over 5.58 % of the total world production of the cotton fiber but only converts 30% into yarn, fabric and apparel for domestic and regional consumption see table below:

Source ICAC

The cotton produced in Africa is spun and woven in Asia, converted into apparels and shipped to USA and EU to be worn for 2-3 years and shipped back into Africa as used clothing to clothe 70% of Africans .

Historical Background:

Cotton, Textile and Apparel sector has witnessed major changes on global policy front over last decade or so, causing major shift in manufacturing and trade patterns. With Multi Fiber Agreement (MFA) being phased out, several countries in Latin America, Europe and Africa lost their share in global trade mainly to Asian countries of China, India, Bangladesh, Vietnam, etc. The LDC and developing countries in affected geographies were the worst hit, where many units closed down as they were no more viable, creating large-scale unemployment. Among these countries were several major cotton producing nations, which started exporting raw fiber without any value addition. Such countries were mainly from Africa – Burkina, Egypt, Zimbabwe, Mali, Nigeria, etc. and Central Asia – Uzbekistan, Turkmenistan, etc.

Importance of the textile and apparel sector:

Cotton, Textile and Apparel sector is one of the important sectors in developing countries across the globe, specifically for those, which have been bestowed with Cotton as one of the natural resources. It not only fulfills one of the basic human needs i.e. clothing, but also provides large-scale employment, specifically at the start of value chain (farming and ginning) and towards the end (apparel manufacturing). The figure below depicts the scope of value addition and employment potential across the CTA sector value chain.

The fact that the annual trade Globally in this segment is in excess of US$ 500 billion also provides opportunity to countries to earn valuable foreign exchange.

Steps taken by various countries for sector development:

At present, the countries where manpower is still inexpensive and cotton fiber is abundantly available like China, India, Pakistan, Brazil, Uzbekistan, etc. are focusing significantly to grow the industry. Ambitious schemes specific to this sector are being launched by federal governments in these countries to boost manufacturing for domestic consumption as well as exports. Similar steps are being taken by countries in Africa as well e.g. Government in Sudan has announced a large package for rehabilitation of many of the textile units, Uganda is implementing a special National Textile Policy to increase investments and make units more competitive in the country, Ethiopia has successfully transformed itself into an investor friendly destination for attracting FDI, etc. On similar lines, Nigeria has also earmarked a fund of N100 billion (~ US$ 650 million) for Cotton, Textile and Garment Industries Revival Scheme. One of the most important impacts of this scheme had been the reopening of the United Nigerian Textile Plc factory in Kaduna, which has recalled thousands of laid off workers.

Background: Cotton Cultivation in Kenya

Cotton was introduced in Kenya in the year 1902 by British Colonial administration. In 1953 the Cotton Lint and Seed Marketing Board was established by the government, whose major role was to undertake production, processing and marketing of the cotton sector. At the same time, the Cooperative Unions were also formed to handle primary activities like input supply and payment to the farmers.

At the time of Kenya’s independence (1963) the industry was dominated by private ginners. Over the next ten years, Government provided a lot of support in the form of a well-organised marketing system and timely payments. In addition to this, the Government also invested in a number of textile mills, which supplied to the large apparel manufacturers.

Till 1991, the Cotton Board of Kenya controlled Kenya’s cotton industry. In 1991, the government decided to liberate the sector and allowed private investors to participate. As a result of this, the government support started declining, which ultimately resulted in the decline in cotton production. In recent years, the production has picked up a bit but has been marred by low market demand and lower returns to farmers.

Cotton Production In Kenya ( In MT) ( 1970-2012) DATA source: National Cotton Council, USA

GDP per Capita Income 1960 – 2010

Today, cotton is mainly grown in Arid and Semi-Arid Areas where there are limited economic activities. It is grown mainly by small-scale farmers in Western, Nyanza, Central, Rift Valley, Eastern and Coast provinces of Kenya. An estimated 200,000 farmers grow most of the cotton on holdings of less than one hectare. Majority of the production takes place in the Eastern zone comprising Coastal, Eastern and North Eastern regions. These regions contribute to ~85% of the production. While the Western zone, comprising Nyanza, Rift Valley and other western regions, contribute to about 15% of the seed cotton production. In Eastern Kenya, the cotton crop is sowed in the month of October whereas in Western regions it is sowed in March.

Necessity for a sector development plan and its key components:

Earmarking a fund for the sector is the foremost step required to be taken by government having sincere plans for revitalization of the sector. Beyond that comes the requirement of a broad vision for the sector, a set of guiding principles to make best use of those funds. While rehabilitating the units may be important where maximum funds need to be committed, but in order to achieve sustainable growth it is important to address the other issues also, to help industry to go that extra mile. This is specifically true for CTA sector where any unit’s viability is a function of several interlinked parameters of raw material, manufacturing and marketing; hence the desired way is to take a holistic view rather than a stopgap arrangement.

The requirement is of developing a comprehensive sector strategy, which addresses the various issues in the sector in most efficient manner. The issues can be high power cost, lack of marketing linkages, low technology level, lack of skilled workforce, absence of incentives to attract FDI, lack of support infrastructure, protection of domestic industry, export incentives, raw material allocation, weak supply chain linkages, etc.

The development of such a strategy will require:

- Mapping of the current status of sector

- Identification of key gaps

- Benchmarking against global leaders

- Developing interventions to address the issues holistically

- Preparing a roadmap for its implementation

How ACTIF can help?

The African Cotton and Textile Industries Federation (ACTIF) is a not for profit regional industry/trade body formed in June 2005 by the Cotton, Textile and Apparel sectors from Eastern and Southern Africa covering the COMESA, SADC and the EAC trading blocks, and currently includes members of National Associations from 25 countries (Botswana, Burundi, Cameroon, Cote d’Ivoire , Egypt, Ethiopia, Kenya, Lesotho, Ghana, Madagascar, Mozambique, Namibia, Nigeria, Sudan, Mauritius, Malawi, Madagascar, Mozambique ,South Africa, Swaziland, Serra Leone , Tanzania, Uganda, Zambia and Zimbabwe).

ACTIF’s milestone achievements include

- MOUs with COMESA and with the East African Community for trade development along the Cotton, Textile & Apparel (CTA) value chain

- Key contributor to the COMESA CTA strategy and now officially recognized as an implementing partner of the strategy

- Participated in EPA negotiations and developed draft RoO for apparel exports to EU under EPA

- Successful developed a common position white paper for our 20 member countries on AGOA

- Currently engaged in an advocacy project towards the sustainability of AGOA in East Africa and also to our other member countries supported by TMEA.

With the funding support of Center for Development of Enterprise (CDE), ACTIF has recently conducted a CTA sector supply side analysis of four countries in Eastern Africa – Kenya, Sudan, Tanzania and Uganda. This comprehensive study is on the similar lines what needs to be done in Nigeria as well.

With the mandate to pursue development of textile sector in Africa, liaison with international donor partners, network with international consultants and experience of doing similar strategy work, ACTIF is well suited to assist Bank of Industry, Nigeria for development of CTA Sector Strategy for Nigeria.

Given the mandate, ACTIF along with partner international and local consultants would start with conducting a comprehensive mapping of Nigeria textile sector. This step would be followed by a fact-based analysis along with benchmarking with global best practices. The ultimate outcome of this exercise will be:

- An As-is analysis of Nigerian textile industry

- Key risks and mitigation strategy

- Identification of opportunities in the sector

- Interventions for sector growth

- Implementation road map