In transit from Bangladesh to Manchester, I walked past the luxury stores in Dubai airport, all of which have leather bags displayed in their windows. The spotlights in the store windows shine down on an array of beautiful bags, but I want to shine a spotlight on a darker story which needs to be revealed. The previous day I had visited the tanneries in Dhaka, Bangladesh, where the leather used for many of the world’s designer bags and shoes originates.

Until recently, the district of Hazaribagh housed the majority of Bangladesh’s tanneries. Not only did severe labour abuse, including child labour, take place but decades of untreated chemical waste has poured into the local Buriganga river, affecting local communities and habitat. In particular, chromium from the tanneries has affected fish populations on which the red-listed endangered Ganges river dolphins prey. Concentrations of chromium are up to 100 times the level prescribed by the World Health Organisation for drinking water.

In an attempt to improve conditions for workers and prevent further environmental pollution in the growing leather sector, the government of Bangladesh decided to relocate the tanneries from Hazaribagh to Savar. The move has been beset by delays: initially scheduled for 2005 completion, an article in Bangladesh’s Daily Star newspaper on 8 November reported that the project has been delayed yet again and they are now aiming for completion in June 2019.

Meanwhile, 92 of the 155 tanneries have already been relocated to Savar, most of which have double the land and therefore at least double the production capacity of their previous facilities. However, the infrastructure and utilities for the tanneries are from adequate, whilst facilities for relocated tannery workers do not even meet their basic necessities of housing, health, education and transportation.

I was visiting unannounced, hoping to talk to workers and managers about the environmental and social problems created by the move. I followed a truck piled high with hides into the Savar Tannery Estate. The smell was a good indication we were approaching the tanneries – a powerful odour which intensified on approach.

The roads were not only potholed, but were covered in surface effluent. The Central Effluent Treatment Plant for the new Savar Tannery Estate is not yet fully functional, drainage systems are not in place and tannery effluent is flowing into local drainage ditches and into the Dhaleswari river. According to the Rapid Assessment of Hazaribagh Tanneries report recently published by SANEM, analysis of data and samples collected at discharge points from the treatment plant, as well as from the Dhaleshwari river, have produced alarming results. Everywhere I looked, drainage ditches were visibly flowing with chemical effluent, with one drain running behind a row of food stalls serving meals to the tannery workers. The government shifted the tanneries due to pollution of the river but ultimately the same thing is happening in Savar.

As I walked from the car towards the first factory I spotted something else on the road – animal tails lying discarded on the ground. Solid waste is being dumped in the streets because a protected dumping yard has not yet been set up.

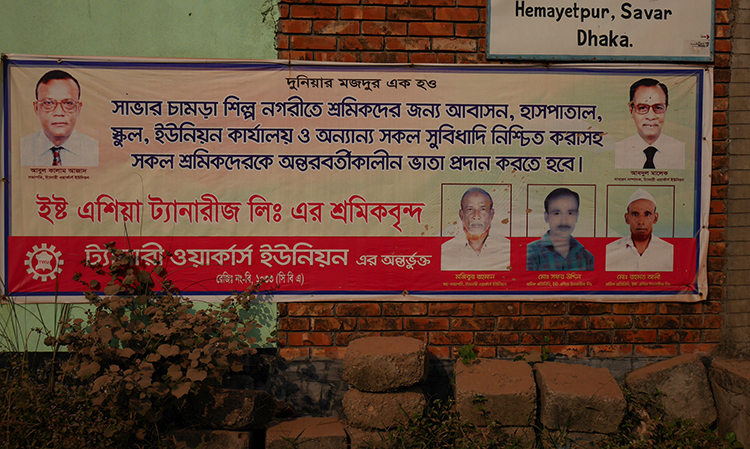

Environmental issues are not the only problems caused by relocating the tanneries before the infrastructure is complete. A sign outside a factory, put up by the Tannery Workers Union, says: “We demand hospital, residence, school, development centre and other benefits should be assured and all past dues should be settled for the workers.”

In the first factory I visited, the foreman was candid about what the urgent improvements needed within the locality. “If there is a serious injury we can’t get the worker to hospital on time. There are no primary healthcare services here. A lot of our workers need ongoing medical support due to skin rashes but we don’t have such facilities here. There is almost no accommodation in the area. There is some but it is expensive so the workers have to commute for 120 taka each way every day (£1.10) and it takes 1.5 to 2 hours. 95% of our country is Muslim yet we don’t have a mosque here.”

I also observed many young workers in the factories, all working without any protective equipment. The sector has an 11% child labour rate, but there is also a problem with young labourers on apprenticeships who should be aged 16 to 17, but often start at 15. Apprentices are allowed to work 30 hours over a six-day week, plus 6 hours maximum overtime across the week, but they are working far more in the tanneries.

Returning to Dhaka, I visited the offices of Awaj Foundation where I talked to Nahidoc Hasan Nayan, Director of Operations, about the tanneries and what steps needed to be taken in order to resolve the myriad problems I had seen that morning. Accommodation costs in Savar are very high compared to Hazaribagh and housing is insufficient, but if workers don’t move the high cost of the commute means their real wages have decreased and they are working below the poverty line. The workers also need schools for their children and medical facilities, which are currently 10-15km from the tanneries. If a factory has 150 workers they should by law have first aid inside the factory but this is not happening. It could easily take over an hour to get to medical facilities due to the traffic jams. Workers are not using personal protective equipment so the risks are high. There is one union for tannery workers, but according to Mr Nayan it is working for the factory owners not the workers.

“Workers are worse off,” stated Mr Nayan,“I found 12 year old boys there last week who have no idea they are working in such a dangerous place.

Part of the problem is that brands don’t come to the tanneries; buyers only engage with the factories,” he continued.

Although the foremen in the tanneries did not know for which brands the leather was destined, I was told in one of the tanneries that the leather would be sent to China and Italy. In Fashion Revolution’s 2017 Fashion Transparency Index which reviews and ranks 100 of the biggest global fashion and apparel brands and retailers according to how much information they disclose about their suppliers, supply chain policies and practices, and social and environmental impact, we found that only 14% of brands were publishing their second tier factories, which sometimes includes tanneries. No one is publishing a list of raw material suppliers, so there is no way for consumers to know where the leather comes from or what animal welfare standards are in place.

The leather and footwear industry is the second largest revenue generator in Bangladesh. Although far behind the Ready-Made-Garment sector at $2 billion USD compared to $28 billion USD, footwear production is expected to become the next area of growth in Bangladesh, putting more pressure on the tanneries as they meet increased demand. The footwear industry comprises 35-50% women but they are not getting maternity leave, nor are workers receiving medical leave or holidays, only festival leave. Not all are getting minimum wage in both the tanneries and the footwear factories, particularly in smaller factories. According to Mr Nayan, only 5-10% of the factories have adequate working conditions.

The move to Savar was planned as a means of improving social and environmental standards but quite the opposite has occurred. So what needs to happen now? Workers urgently need compensation for the wages they lost during the 3 to 4 month transition period from Hazaribagh to Savar when they were unable to work. Transportation must also be organised for workers until affordable, local accommodation is in place. The Central Effluent Treatment Plant urgently needs completion as the current situation is just moving environmental pollution from one site to another. Ultimately, all stakeholders need to take measures to improve working conditions, benefits and health and safety standards so this move has a positive long-term effect on the environment, workers and their families.

As consumers, we can also play a part by asking the question #whomademyclothes, telling brands we need more transparency in fashion supply chains right back to the tanneries and the raw materials.

Many of the social and environmental problems we are seeing in the tanneries are the same ones that beset the garment factories from their inception in the early 1980s until post- Rana Plaza scrutiny started to bring about change. As the leather sector expands in Bangladesh, let’s not make the same tragic mistakes we made with the garment industry.

Carry Somers visited Bangladesh as a guest of the Bangladesh Denim Expo which this year had a focus on Transparency.

For further information on the Rapid Assessment of Hazaribagh Tanneries report, see SANEM

Textile Exchange has set up the Responsible Leather initiative to create responsibility in the leather supply chain.

Fashion Revolution’s inaugural Open Studios project was designed to open up the conversation about how clothes are made: to show some of the many processes involved; to give the public who don’t normally have access to the often secretive behind the scenes business of the fashion industry; and to give a platform to some of the designers who are actively finding different ways of producing and selling their collections.

For the designers, this was an opportunity to talk about their clothes and the craftsmanship that goes into making them away from the traditional catwalk format which many new generation designers (and some more established ones) are no longer comfortable with.

A new way of talking about clothes

Fashion is going through a massive shift right now. It’s time to rethink the whole business, from how clothes are made to how they are shown and talked about. Everything is up for question. How many seasons should there be? Is the catwalk show a waste of money (and air miles)? How does a designer communicate most effectively to their community? How does a designer find his or her community?

What is becoming clear is that having an authentic story – whether that’s about the provenance of your materials, the way you make your clothes, your supply chain, or your manufacturing process – resonates with the public. If people trust you and your brand values, they are more likely to become loyal clients.

For young, independent designers, the marketplace is an increasingly crowded one. The gap between the big multi-conglomerate owned brands and independent designers is getting bigger. Even if you have something to say, it is difficult to make your voice heard. But at the same time, the industry is looking for answers and it is the smaller brands who are finding innovative new ways of doing things. Fashion Revolution Open Studios is the perfect place to start those conversations.

Open Studios is an international initiative which is set to expand for 2018. In California, Raquel Allegra hosted a tie-dye workshop in her downtown LA store, showing participants how to dye their own clothes. She also used the opportunity to introduce some of the team who work on the production of her clothes.

Meanwhile, in New York, Audrey Louise Reynolds held an open studio at her Brooklyn Red Hook space showing how she uses vegetable and natural dyes for her delicate pastel pink and turmeric yellow colour palette with advice on how to use her DIY natural dye sachets too. Reynolds has collaborated with Jigsaw as well as Helena Christensen and you can see why her work is in such demand. Read more on WGSN.

And in Jakarta in Indonesia, one of the country’s hottest young designers Wilsen Willim hosted a shirt making workshop at the Indoestri Makerspace. Willim’s signature is the shirt dress which he creates in seemingly endless inventive variations. Willim makes use of the innovative digital startup Kostoom.com which connects him with a network of seamstresses to do his production as piece work which means he, and other small designers, can produce small quantities and scale up or down whilst providing work to tailors working at home.

Studios as creative hubs

Christopher Raeburn embraced the format wholeheartedly. Since moving into his studio space in the old Burberry factory in east London’s Fashion Village, he has been welcoming the public in for studio tours including his archive of vintage military clothing as well as his own collections. He has also started a series of maker workshops where you can learn to cut and sew your own piece of Christopher Raeburn with a little help from his seamstresses and design team. He enjoys welcoming his local community in to see what he is doing.

“I am very proud of my studio,” he said, “and like to open it up as a creative and community hub whenever I can, with regular workshops to teach people how to sew as well as how to repair and customise their clothes and accessories.”

For Open Studios 2017, he hosted a series of open studio tours as well as a “Totes Remade” evening showing guests how to sew their own bag from scrap fabric, and with sponsor Avery Dennison RBIS, created a huge selection box of patches (made from recycled yarn) to decorate the bags. It was quite a party.

“I was very proud to open up the REMADE studio and be a part of Fashion Revolution Week and #whomademyclothes campaign,” said Raeburn. “The tote making workshops were very rewarding events that brought lot of creativity out of the local community.”

Make your own

A real trend that emerged from Open Studios 2017 was a move towards involving the consumer in the process of making their own clothes. Katie Jones held an intimate workshop at her Cockpit Arts space in partnership with Beyond Retro. She taught her participants how to crochet patches to customise or repair existing clothes. It was an opportunity to learn some new skills, meet the designer (and eat lots of Haribos) and learn about her business and craft, but also to make something useful. She’s extending this idea into her practice more and more – keep an eye on her website for in-depth workshops you can join where making your garment is part of the process of owning it. Katie believes that fashion is as much about your relationship with the garment as it is just owning it. It’s not enough to just buy it off the peg (though of course, I’m sure she would welcome that too!) Sign up to get news of her upcoming workshops here

A platform to exchange and share new ideas

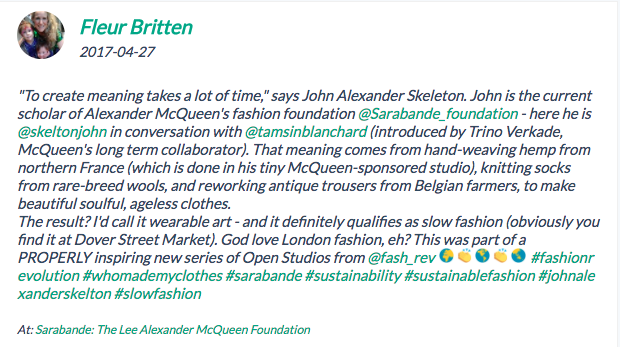

As well as workshops as ways to learn a new skill and understand how our clothes are made, Fashion Revolution Open Studios is the ideal platform to discuss and exchange new ideas. We partnered with the Sarabande Foundation for a talk with John Alexander Skelton, one of the most exciting and original new talents to emerge from Central Saint Martins. Skelton looks at his supply chain with forensic detail and creates extraordinary menswear collections using traditional handloom weaving techniques as well as sourcing woven fabrics and knits from local British suppliers. He is forging a new way of producing and selling collections that have, at their heart, an intrinsically ethical and transparent supply chain. Guests were given the rare opportunity to meet John and see his studio, complete with a weaving demonstration. It was a memorable and thought provoking evening, well attended by students, press and industry insiders.

This is Fleur Britten, fashion editor of the Sunday Times’ take on the evening:

The only fashion week worth caring about

There was so much great support and enthusiasm for Fashion Revolution Open Studios 2017, not least from The Debrief who described it as “the only fashion week worth caring about” (we think so, too), as well as Refinery29, Vogue, 10 Magazine, Tank, Sleek, and many others websites and influencers. It was a phenomenal success.

Also taking part in the week’s events were The Autonomous Collections with Kim Stevenson and her ‘ethicool’ workshop where she invited participants to help make a garment; Jodie Ruffle, the extraordinary embroiderer whose recent collaborations have included a project for Adwoa Aboah’s brilliant Gurls Talk Embellished Talk project; Blackhorse Lane Ateliers which hosted a series of open studio events with tours of a unique workshop hand-crafting British made jeans; and the entire textile city of Prato in Italy which staged several workshops and events, coordinated by Italy’s Fashion Revolution country coordinator, the veteran designer Marina Spadafora.

We are in the process of planning Fashion Revolution Open Studios 2018. We have so much to build on, and can’t wait to announce the new line up, hopefully with an event you can take part in near you (or at least online). So stay tuned and thank you for all the amazing support and to all the designers for sharing their stories, their brilliance, and their creativity.

Ethical Fashion Initiative is a flagship programme of the International Trade Centre, a joint agency of the United Nations and the World Trade Organization. The Initiative links the world’s top fashion talents to marginalised artisans – the majority of them women – in East and West Africa, Haiti and the West Bank. Active since 2009, the Initiative enables artisans living in urban and rural poverty to connect with the global fashion chain. The Ethical Fashion Initiative also enables Africa’s rising generation of fashion talent to forge environmentally sound, sustainable and fulfilling creative collaborations with local artisans.Under its slogan, “NOT CHARITY, JUST WORK.” the Ethical Fashion Initiative advocates a fairer global fashion industry.

Over the past few seasons the Fondazione Pitti Discovery has been setting aside a special area for the rising stars on the world’s economic and creative stage with the Guest Nation project. This edition, in cooperation with the ITCEthical Fashion Initiative, focussed on fashion from Africa with a special event “Constellation Africa”, to promote young and talented designers from the continent.

“I believe that Pitti Uomo is the best platform to showcase these innovative designers from Africa, the continent which hosts the future of fashion and couture“, says Simone Cipriani, Head and Founder of the ITC Ethical Fashion Initiative. “The richness of materials and the beauty of their designs are truly unique. This is where our global society is going: interconnectedness. Global and local dimensions brought together through fashion“.

The four participating brands were:

ORANGE CULTURE // Adebayo Oke-Lawal from Nigeria

Orange Culture is a contemporary menswear brand created by Nigerian designer Adebayo OkeLawal in 2011. The brand combines classic and contemporary western silhouettes with an African edge. Orange Culture fuses Nigerian silhouettes, print fabrics and contemporary urban streetwear. Orange Culture is more than a clothing line, it is a “movement” for a creative class of men that are “self-aware, expressive, explorative and art-loving nomads”. Orange culture has been featured by top fashion magazines and was recently shortlisted by Vogue Talents for Africa and LVMH’s 2014 Young Fashion Designer Prize.

MaXhosa by Laduma // Laduma Ngxokolo from South Africa

MaXhosa by Laduma is a South African knitwear brand founded in 2010 by Laduma Ngxokolo. The South African Xhosa manhood initiation ritual practiced by amakrwala was behind the launch of the brand as Laduma sought to create Xhosa-inspired modern knitwear that would be suitable for this tradition. Since, the Xhosa aesthetic has come to be part of the DNA of the knitwear brand as Laduma has explored and reinterpreted traditional Xhosa beadwork, patterns, symbolism and colours to inspire his modern knitwear line. Through his work, Laduma is an agent of change, shifting and evolving with the changing times and further engaging in the dialogue that keeps pushing traditional culture toward the future.

PROJECTO MENTAL // Tekasala Ma’at Nzinga & Shunnoz Fiel from Angola

Projecto Mental is an Angolan fashion brand, founded in 2004 by creative duo Shunnoz Fiel & Tekasala Ma’at Nzinga, which fuses fashion and art. The brand was created in the aftermath of the civil war as a platform to help reshape Angola’s cultural identity, after the country was ravaged by decades of civil war. Suits with an experimental twist are the signature item of the Projecto Mental brand. Projecto Mental takes an avant-garde approach to tailoring as the designers re-imagine and re-invent the traditional suit for men and women. Strong block colours combined with prints & patterns bring boldness to each design.

DENT DE MAN // Alexis Temomanin from Ivory Coast & UK

Dent de Man is a menswear brand created in 2012 by British-Ivorian designer, Alexis Temomanin. Dent de Man’s approach to luxury style is defined by a mix of classic tailoring with colourful patterned fabric. The Dent de Man lifestyle is defined by freedom, quality and “esthétisme”, empowering individuals to dress for themselves. Self-expression is core to Dent de Man’s philosophy. The brand prides itself on the use of vintage fabrics and celebration of ancient printing techniques, Dent de Man adapts decadent and bold Java prints forming unique garments that allow individuals to own distinctive and irreplaceable pieces. All Dent de Man fabric is carefully sourced and possesses its own story and meaning.