Material Shake-ups for Ecology’s Sake

On the journey towards more sustainable clothes, material innovations are one of the fashion industry’s greatest levers for change. We were recently reminded by The Sustainable Angle that material choice can account for up to 95% of a product’s social and environmental impact. On that note, we turned to a couple of the experts imagining new textiles to create products with revolutionary footprints.

EVERYBODY.WORLD, the part-brand, part-think-tank, part-innovation hub, has been emphasizing textile responsibility since its inception. Iris Alonzo, EVERYBODY’s co-founder and creative director, attributes this to her previous industry experience, where she was made well aware of fashion’s track record on waste. Iris tells us that the aim was, “To be a part of the solution, rather than continue to contribute to a problem.”

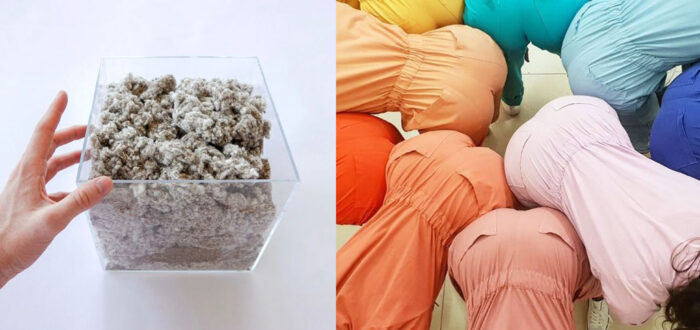

So the duo (Alonzo along with her co-founder, Carolina Crespo) took a unique approach to textile recycling. Until now, most recycled textiles are synthetic – nylon and polyester – because the production process of these materials allows them to more easily be melted back down into their basic building blocks. But Iris and Carolina weren’t deterred by industry precedent. They eventually developed a cotton recycling process that collects the ‘cotton dust’ (waste) from cotton spinners and repurposes it into new cotton yarn.

“That’s where our journey started and it involved about a year of R&D in the areas of yarn, textile and garment development. The result was the Trash Tee, and it truly was the very first 100% recycled cotton t-shirt on Earth.”

While we generally think of recycling as the breakdown and regeneration of a material, the EVERYBODY method is actually more about regenerating waste. Iris explains: “When yarn is spun from raw cotton, there’s a huge amount of byproduct that comes out of the process. That usually goes to landfill or sometimes has a down-cycling outlet. We save and collect that waste from various American yarn factories and then without water, we mechanically clean the waste and reprocess it to make a new yarn. The yarn is then knitted into fabric (jersey for the Trash Tee and fleece for the hoodies).”

The story of the Trash Tee is equal parts awe-inspiringly impressive and fundamentally frustrating. This latter feeling occurs when you consider that small brands, like EVERYBODY, with fewer resources and capital can design their way out of waste, yet too many of the biggest brands continue to do so little in the way of material responsibility. It feels unfair. And yet, the more that citizens demand responsible clothing, the more that the big players will get on board. In recent weeks, the Coachella music festival announced its official hoodie merch would be made from EVERYBODY’s recycled cotton fleece. And so with one of the world’s most renowned festivals taking a stand through its webshop, the hope is that more events, companies, and retailers will step up.

Of course, some of the best ideas start small. In her recent Ted Talk on the potential of Biofabrication, materials expert Suzanne Lee noted, “In the last century, we expected material innovation to come from the likes of DuPont, Dow, and BASF. But this 21st century material revolution is being lead by startups, with small teams and limited capital.”

Enter Pangaia. The materials science company was founded on the premise of making clothes with a lesser impact on resources. Pangaia’s chief innovation officer, Dr. Amanda Parkes, tells us a little bit about the company’s ethos, which is “Focused on ‘high tech naturalism’ which involves using existing natural materials, like agricultural waste, that are augmented by scientific and technology processes”. Amanda’s path to Pangaia, bubbling up from a discomfort with business-as-usual follows a similar plotline to Iris’s, “witnessing the dangerous and excessive waste created by the tech industry and questioning the status quo of how and why things are made the way they are.”

Chief innovation officer might sound like a very cool, but mostly mysterious job title, but Amanda defines her role as, “‘Scientific Diplomacy’ – getting people from different backgrounds and skill sets to understand each other, communicate better and together create a product development plan and process that balances the issues and priorities of scientific innovation with existing systems of factory production and fashion branding.”

And if you’ve heard of Pangaia in recent months, it’s probably thanks to one of their recent inventions. This new technology subverts Meryl Streep’s iconic line in The Devil Wears Prada (“Flowers? For Spring? Groundbreaking”). See, Pangaia recently introduced flowers for Winter, and in a way that’s groundbreaking minus the sarcasm. The floral matter replaces traditional feather down, and its polyester counterpart, with a new form made from dried flower waste.

Why? “The traditional goose down industry generally involves considerable animal cruelty, where the birds are plucked alive or killed exclusively for their feathers, as well as increasing the overall environmental cost (crops for feed, water, land use etc) of raising the animals. However, vegan alternatives to down are typically made of petrochemical based synthetics that shed polluting microplastics when washed and do not biodegrade at the end of the garment’s lifecycle”, says Amanda, “FLWRDWN provides a sustainable solution that addresses both of these issues – it is vegan, natural, hypoallergenic and completely biodegradable while also providing comparable performance characteristics- meaning it has the warm, cozy, fluffiness of high quality traditional down.”

Asking her to explain the creation process in a way that doesn’t completely scare the non-science-oriented among us, Amanda unfolds the basic recipe. “The components of FLWRDWN are wild flowers that have been sustainably harvested, and combined with a biopolymer and cellulosic aerogel.” If that latter ingredient sounds unfamiliar, think of it as a cloud-like material, essential for insulation, and which Pangaia creates from 85% recycled paper.

Beyond the excitement conjured by wearing potpourri inside our puffer jackets, our conversation with EVERYBODY.WORLD and Pangaia reinforced the important notion that sustainability isn’t one thing; it’s a diversity of solutions.

As Amanda put it: “Sustainability is always a series of compromises based on priorities and we need a lot of people doing some things better rather than a few people doing everything perfectly.”