Makati City, Philippines – In a groundbreaking collaboration, Fashion Revolution Philippines, iAcademy, and Lee Jeans Philippines have come together to create a unique and sustainable fashion collection. The project, dubbed “Segunda Mana,” showcases the power of upcycling and the ingenuity of Filipino design students.

A Second Life for Denim

Lee Jeans Philippines donated a trove of old denim stock to iAcademy, challenging the students to transform the materials into a modern streetwear collection. Under the guidance of fashion designer and teacher Irene Grace Subang, the students delved into the art of deconstruction and draping, using Filipino mysticism and superstitions as their inspiration.

The “Segunda Mana” collection is a testament to the creativity and resourcefulness of the iAcademy students. By working exclusively with upcycled denim, they not only reduced their environmental impact but also created pieces with a unique story to tell. The collection’s intricate designs and thoughtful use of materials showcase the potential of sustainable fashion.

Showcasing Filipino Talent

A portion of the “Segunda Mana” collection was featured during iAcademy’s SODA Week, providing a platform for the students to showcase their work to a wider audience. The event culminated in a fashion show featuring designs from both current and former iAcademy students, highlighting the school’s commitment to nurturing young talent.

The collaboration between Fashion Revolution Philippines, iAcademy, and Lee Jeans Philippines is a significant step towards promoting sustainable fashion in the Philippines. By demonstrating the possibilities of upcycling and the creativity of Filipino designers, the project has the potential to inspire others to adopt more environmentally conscious practices.

Manila, Philippines – A unique blend of biking, art, and sustainability came together in a recent community event that empowered participants to create their own eco-friendly fashion accessories. The “Bike and Bandana” activity, hosted in Quezon City and Manila, offered a fun-filled day of cycling, eco-printing, and delicious organic treats. Participants began their journey at Centris Mall in Quezon City, where they embarked on a leisurely bike ride to Dangwa Market in Manila lead by Jeza Rodriguez. The market, known for its abundance of flowers, provided the perfect opportunity for participants to select their favorite blooms for their eco-printing project.

Participants began their journey at Centris Mall in Quezon City, where they embarked on a leisurely bike ride to Dangwa Market in Manila lead by Jeza Rodriguez. The market, known for its abundance of flowers, provided the perfect opportunity for participants to select their favorite blooms for their eco-printing project. After gathering their floral treasures, the group cycled back to Quezon City and headed to the lagoon in UP Diliman. Here, under the guidance of artist Rosa Mirasol, participants learned the art of eco-printing. Using leaves, flowers, and a hammer, they imprinted their chosen designs onto pieces of linen, creating one-of-a-kind bandanas.

After gathering their floral treasures, the group cycled back to Quezon City and headed to the lagoon in UP Diliman. Here, under the guidance of artist Rosa Mirasol, participants learned the art of eco-printing. Using leaves, flowers, and a hammer, they imprinted their chosen designs onto pieces of linen, creating one-of-a-kind bandanas. The eco-printing process not only allowed participants to express their creativity but also fostered a deeper connection with nature. By using natural materials and avoiding harmful chemicals, they created sustainable and personalized fashion accessories.

The eco-printing process not only allowed participants to express their creativity but also fostered a deeper connection with nature. By using natural materials and avoiding harmful chemicals, they created sustainable and personalized fashion accessories. To fuel their creative energy, participants enjoyed a delicious spread of organic delicacies prepared by Lei Azarcon from Luntian Life. Pako salad, pastil, and Geno’s Gabi ice cream were just a few of the delectable treats that delighted taste buds.

To fuel their creative energy, participants enjoyed a delicious spread of organic delicacies prepared by Lei Azarcon from Luntian Life. Pako salad, pastil, and Geno’s Gabi ice cream were just a few of the delectable treats that delighted taste buds.

The “Bike and Bandana” event was a collaborative effort between Make It Safer Movement (MISMo), Bikeary Bicycle Lifestyle, BudolBuddy, and Fashion Revolution Philippines. This partnership brought together like-minded individuals who are passionate about sustainable living, community engagement, and creative expression.

As participants left the event with their newly created bandanas, they not only had a beautiful and unique accessory but also a sense of accomplishment and a deeper appreciation for eco-friendly practices. The “Bike and Bandana” activity was a resounding success, showcasing the power of community, creativity, and sustainability.

On May 19th, 2024, Rizal Park Luneta transformed into a vibrant canvas of culture and eco-consciousness. The National Parks Development Committee (NPDC) joined forces with Fashion Revolution Philippines, SoFA Design Institute, and Urban Sketchers Manila to present a unique Flores de Mayo celebration: Fashionista Flores de Mayo.

This exciting event wasn’t just about religious devotion or showcasing stunning gowns. It was a beautiful fusion of tradition and environmental awareness. SoFA design students presented modern Filipiniana gowns and suits, all crafted with sustainability in mind.

The festivities began at 5:00 pm, with Urban Sketchers Manila capturing the elegance of the “Reinas” (Queens) in their one-of-a-kind attire. As the day unfolded, the Santacruzan parade filled the air with a celebratory energy, snaking its way through the Central Section of Rizal Park.

The festivities began at 5:00 pm, with Urban Sketchers Manila capturing the elegance of the “Reinas” (Queens) in their one-of-a-kind attire. As the day unfolded, the Santacruzan parade filled the air with a celebratory energy, snaking its way through the Central Section of Rizal Park.

The highlight of the evening was the Santacruzan fashion show, held at the Open-Air Auditorium. Here, the public witnessed a modern interpretation of the Santacruzan tradition, where sustainable fashion took center stage.

But the sustainable fashion movement didn’t end there. From May 21st to 26th, an exhibit titled “Modern Filipin(ian)a: Reimagining Santacruzan Gowns” took place at The Gallery of Rizal Park Luneta. Visitors were invited to get a closer look at the eco-conscious gowns, sparking conversations about responsible fashion choices.

The Fashionista Flores de Mayo was a resounding success. It proved that cultural celebrations and environmental consciousness can go hand in hand, paving the way for a more sustainable future for fashion in the Philippines.

Isabela State University in Ilagan City is at the forefront of a textile revolution! The Philippine Textile Research Institute (PTRI) has set up a facility there to create yarn and thread from bamboo – a sustainable and versatile material.

This isn’t just about replacing cotton with bamboo. PTRI is blending bamboo with cotton to create unique yarns perfect for clothing. Imagine – government uniforms made with Philippine-developed, eco-friendly bamboo fabric!

Ilagan City’s commitment to sustainability aligns perfectly with PTRI’s vision. The yarn production process is automated, minimizing waste. Plus, they cleverly recycle scraps into new threads! This innovative facility produces 50kgs of yarn every 8 hours, paving the way for a greener textile industry.

The future of textiles is being woven right here in Ilagan City, and it’s made from bamboo!

The Philippines’ longest-running vegan festival, Vegfest Pilipinas, recently celebrated its eighth year with a special event: the ReWork Runway. This eco-vegan fashion show showcased five collections of sustainable and ethical fashion, demonstrating the creativity and innovation that can be found in the world of plant-based clothing.

Why Vegan Fashion?

The fashion industry is a major contributor to environmental pollution, using vast amounts of water and chemicals to produce fabrics and dyes. It is responsible for the exploitation of animals, with leather and other animal by-products being used in clothing. Vegan fashion offers a more sustainable and ethical alternative, using plant-based materials and avoiding the use of animal products. It is a growing trend, with more and more people becoming aware of the environmental and ethical impact of their clothing choices.

The ReWork Runway

The ReWork Runway featured five collections from a variety of designers and brands:

● Irene Grace Subang: A fashion designer and teacher who advocates upcycling. Subang’s collection showed how old denim and textile scraps can be combined to create new and exciting pieces. One of her eye-catching piece has a book leaf design on the right shoulder matched with the pinwheels patterns.

● Re.Clothing: A brand that embroiders and redesigns unwanted clothes to give them new life. The embroidery makes the clothes more personal for the wearer.

● TelaStory Collective: A brand that manufactures and sells garments that set a good living wage of their female artisans. Their clothing collection shows simplicity inspired from a checker design.

● ProjectPH: A brand that uses repurposed white flour sacks to create modern and stylish clothing. This practice dates back in late 1800s but trend went further in the 1929 Great Depression when women repurposed these while flour sacks into clothing.

● ProjectPH: A brand that uses repurposed white flour sacks to create modern and stylish clothing. This practice dates back in late 1800s but trend went further in the 1929 Great Depression when women repurposed these while flour sacks into clothing.

● Euphoria: Ella Alacron‘s collection, a designer whose collection showcased the versatility of denim. Alacron reveals her better woman in redesigning used denim to show more skin.

A special participation from Leby Le Moria. Her handwoven modular piece from off-cut fabric presented from the start of the runway.

A special participation from Leby Le Moria. Her handwoven modular piece from off-cut fabric presented from the start of the runway.

A Celebration of Creativity and Sustainability The ReWork Runway was a resounding success, demonstrating the potential of vegan fashion to be both stylish and sustainable. The collections showcased a variety of innovative designs and techniques, proving that there is no need to sacrifice style for sustainability. The event helped to raise awareness of the importance of ethical fashion choices. By highlighting the environmental and ethical impact of the fashion industry, the ReWork Runway encouraged attendees to make more conscious choices about the clothes they wear.

The Final thought

The ReWork Runway was a powerful event that celebrated the creativity and sustainability of vegan fashion. It showed that there is a growing movement of designers and brands who are committed to creating stylish and ethical clothing. As more and more people become aware of the importance of sustainable fashion, we can expect to see even more innovative and exciting designs in the years to come.

Míg a divatbemutatók önmagukban az iparág környezeti hatásának csak egy kis töredékét teszik ki, Rachel Arthur szerint a divatbemutatók a bolygót károsító túlfogyasztást tápláló marketinggépezet középpontjában állnak.

Racher Arthur tanácsadó, író és az ENSZ Környezetvédelmi Programjának fenntartható divatért felelős vezetője és az ő cikkét adjuk közre magyar fordításban.

Az elmúlt hetekben a divatszakma visszaáramlott Párizsból, a luxusipar kétévente megrendezésre kerülő női divathét utolsó és legpompásabb állomásáról.

Vásárlók, hírességek és influencerek százai repültek oda benzinfaló repülőjáratokon, hogy egy pillanatra bepillantást nyerjenek az új kollekciókba, amelyeket gondosan megmunkáltak egy olyan elavuláshoz, amely azt jelenti, hogy mindenki hajlandó lesz újra repülőre ülni, és hat hónap múlva újra megismételni az egészet.

Az biztos, hogy az ezekkel a nagyszabású marketing pillanatokkal közvetlenül összefüggő kibocsátások és hulladékok csepp a tengerben az iparág teljes lábnyomához képest. Az évek során a márkák és a divattanácsok erőfeszítéseket tettek mindkettő csökkentésére.

A bemutatók közvetlen hatására való kizárólagos összpontosítás azonban figyelmen kívül hagyja a nagyobb képet: a divat negatív környezeti és társadalmi hatásának középpontjában a túltermelés és a túlfogyasztás áll. És mit tesznek a divathetek, ha nem mindkettőt táplálják? Vegyük csak a közelmúltbeli New York-i, londoni, milánói és párizsi rendezvények sorát, nem is beszélve a gyakran túlzó módon megrendezett és elő-őszi kollekciókról – minden egyes bemutató beindít egy marketinggépezetet, amelynek célja az új termékek vásárlásának ösztönzése. Az események által inspirált trendek, az általuk biztosított médiaérték és végső soron a vásárlás, amelyre mindezek ösztönöznek, táplálják a környezeti hatásukat.

Ez a divatbemutatók úgynevezett “agylenyomata”: a kifutón való megjelenésnek a fogyasztásra gyakorolt hatása.

“Ha a lábnyomod a működésedet írja le, akkor az agynyomod azt írja le, hogy az embereket milyen érzésekkel töltöd el. Ez az Ön kulturális lenyomata” – mondta Lucy Shea, a Futerra változási ügynökség csoport vezérigazgatója.

A divatbemutatókra költött milliók nem csak a kifutó kollekciók értékesítését mozdítják elő, hanem a szomszédos és könnyebben hozzáférhető termékek – a táskáktól az illatokig – sokkal szélesebb körű fogyasztását ösztönzik, valamint a tömegpiaci másolatok iránti keresletet is.

A reklámipar felismerte ezt a dinamikát. A Purpose Disruptors, egy korábbi reklámszakemberekből álló szervezet, amelynek célja az éghajlatváltozás katalizálása, bevezette a reklámozott kibocsátás fogalmát, amely a kampányok által generált forgalomnövekedés mérésére utal. Ez azt mutatja, hogy a reklámok 32 százalékkal növelik az Egyesült Királyságban minden egyes ember éves szén-dioxid-kibocsátását.

Talán szükségünk lenne egy ezzel egyenértékű elszámolási folyamatra a divatmarketing számára. Nevezzük el “trendkibocsátásnak” – egy olyan mód, amellyel mérhető a luxus imázsépítés által vezérelt fogyasztás hatása.

Ez azért fontos, mert a divat csak akkor fogja elérni fenntarthatósági céljait, ha csökkenti az eladott termékek mennyiségét. De a luxus agynyomása – a divatbemutatóktól kezdve a szerkesztőségi fotózásokig, reklámkampányokig és influencer posztokig, amelyeket elősegítenek – jelenleg az ellenkezőjére ösztönöz, arra buzdítva a vásárlókat, hogy vásároljanak a villámgyorsan változó trendeknek

Ezt az ENSZ Környezetvédelmi Programja és az ENSZ Éghajlatváltozással foglalkozó szervezete a Fenntartható divatkommunikációs útmutatóban (Sustainable Fashion Communication Playbook) https://www.unep.org/interactives/sustainable-fashion-communication-playbook/ állapította meg. Ez egy felhívás a túlzott fogyasztás üzeneteinek felszámolására, beleértve a hagyományos divatbemutatókat is, és ehelyett a fenntartható fogyasztás irányába kell terelni az erőfeszítéseket.

Ennek nem kell a divathetek halálát jelentenie – ahogyan a fenntartható divatágazat sem követeli meg a divat teljes megszűnését. De mindkettő radikális változást igényel.

Az olyan bemutatók, ahol milliókat költenek a gazdagság pillanatnyi és extravagáns fitogtatására (mindezt azért, hogy a kapcsolódó márka- és médiaértékből további milliókat nyerjenek vissza), nem aktuálisak egy olyan időszakban, amikor iparágként hozzájárulunk a bolygórendszerek eróziójához, amelyektől a túlélésünk függ, és eközben emberek millióit sújtjuk, főként a fejlődő országokban.

Ez áll a középpontjában annak, hogy Amy Powney, a fenntarthatóságra összpontosító Mother of Pearl luxusmárka kreatív igazgatója miért nem tart többé divatbemutatókat.

“Az éghajlati összeomlás idején ez durvának és szükségtelennek tűnt” – mondta. Ehelyett arra kellene használnunk az ilyen alkalmakat, hogy támogassuk és ünnepeljük azokat, akik megmutatják, hogy másképp is lehet.

A koppenhágai divathét az alternatív megközelítés egyik példája: A tervezőknek 2023-tól 18 konkrét fenntarthatósági követelménynek kell megfelelniük ahhoz, hogy bemutatót tarthassanak. Többek között nem szabad megsemmisíteniük a korábbi kollekciók eladatlan ruháit, a bemutatott ruhák legalább felének jobb anyagokból kell készülnie, és a márkáknak vállalniuk kell, hogy platformjaikat a vásárlók oktatására és tájékoztatására használják a fenntarthatósági gyakorlatukról. Bár van még hova fejlődni, más nagyvárosokkal összehasonlítva ez egy nagy nyilatkozat.

Most azokra van szükségünk, akik ismét nagyobb léptékben gondolkodnak arról, hogyan mutassuk be a divattal való kapcsolat új módjait. Végül is ez már nem a fokozatos változás ideje. Az átalakulást fel kell turbózni, új rendszereket és üzleti modelleket kell kifejleszteni – olyanokat, amelyek nem arra épülnek, hogy egyszerűen egyre több és több új dolgot adnak el, és nem gondolnak az emberekre, a bolygóra, sőt a profitra gyakorolt hosszú távú hatásokra. A divatbemutatók újragondolása ennek része.

A divat maga is felismerte a változás szükségességét. A világjárvány idején az iparágon belül egyre többen kérték, hogy reformálják meg a divathetek könyörtelen forgását, ami a független tervezők számára pénzügyileg bénító lehet.

Ahelyett, hogy a platformok egy elavult, elromlott rendszert táplálnának, a divatheteknek lehetőséget kellene adniuk egy új rendszer elképzelésére. A márkáknak arra kellene használniuk őket, hogy rávilágítsanak a megoldásokra, valamint hogy felemeljék és ösztönözzék a tudatos fogyasztás körüli törekvéseket. Erre már vannak példák. Az idei szezonban Párizsban Stella McCartney a kifutón tartott bemutatóját az alacsonyabb környezeti terhelésű anyaginnovációk piacával egészítette ki. New Yorkban Maria McManus tervező a bemutató végeztével a közönséggel együtt végigvezette, hogyan készültek az egyes darabok a fenntarthatóság jegyében.

Ünnepeljük azokat is, akik a körforgásos megoldásokat helyezik előtérbe; azokat, akik a hulladékot erőforrássá alakítják, és arra ösztönzik a fogyasztókat, hogy szeressenek bele az olyan fogalmakba, mint a használt és újrahasznosított divat. Egy párizsi divathét csereboltja, amelyben a szokásos első soros versenyzők is részt vennének, nem csak hatalmas nyilatkozat lenne, hanem talán az egyik legnagyszerűbb divatbemutató, amelyet a mai divatipar valaha is látott.

Itt van egy kreatív lehetőség arra, hogy az ember használja az agylenyomat erejét, és új utat kovácsoljon. Bár a kreativitást nem szabad korlátozni, azt feltétlenül át kell irányítani.

Did you miss some of the events that we got involved in this month? Not to worry, here is what we did early this October.

Fashion Revolution Philippines (FashRevPH) marked the World Circular Textile Day with a series of events. World Circular Textile Day is celebrated each year on October 8 but one day was not enough for this year 2023.

Exhibit and Bazaar at Eastwood Plaza

FashRevPH joins an exhibit and bazaar at Eastwood Plaza in Quezon City with WearForward and Restore. The event featured a well-curated selection of sustainable fashion brands, a clothing swap party with free consultation on sustainable fashion practices, and a showcase of upcycled pieces from Jan Paul Martinez, a local fashion designer. This activity ran from October 6 to October 10.

The Challenges and Opportunities in Textile Waste

Tere Arigo, FashRevPH Country Coordinator, facilitated the virtual panel discussion titled “Closing the Loop: Navigating the Challenges and Opportunities in Textile Waste.” Top industry figures from diverse backgrounds joins the panel discussion. The panel started off with FashRevPH spokesperson Prince Jimdel Ventura of WearForward followed by Noreen Baustista the co-founder of Panublix, joined with her is a fashion educator and sustainable designer Irene Subang, with a professional wardrobe stylist and author of Always Be Chic Miss KC Leyco and lastly Lester Dellosa an environment activist who is also the founder and creative director of CICCADA.

The time for discussion of environmental and economic challenges posed by textile wastes in the Philippines was not enough. It included the innovative solutions that can transform these issues into opportunities for circular fashion materials, processes, business models, products, services, and consumption were too broad to talk about in just an hour.

Capacity Building Workshop on Textile Circularity

FashRevPH collaborated with MakeSense Philippines in a Capacity Building Workshop on Textile Circularity on October 13, 2023. The workshop was held at BSA Twin Towers in Ortigas Center, Mandaluyong City.

FashRevPH participated in the workshop to talk about local textiles and sustainable fashion with Mr Ventura as part of the panel in the first part of the program. The organization guided the design of one of MakeSense’s capacity-building workshops in partnership with the United Nations Development Programme (UNDP).

FasRevPH’s Commitment to Sustainability

FashRevPH is committed to promoting sustainable fashion in the Philippines. The organization works to educate consumers about the impact of their fashion choices and to encourage them to support a more sustainable approach.

Manila, Philippines – Wine gets better with age and so does clothes where they gets fabulous with decades. That’s what vintage fashion is all about, give second chances to old clothes. The last Sunday of the May held a vintage community flea market where you can grab as many old clothes as you can.

The vintage community flea market ran a one day event on 28th of May 2023 called “Second Chances” at the Escolta street, Manila. The First United Building hosted the Second Chances event at the first floor. Appropriately, the vintage Art Deco building’s first floor housed the popular Berg’s department store before the malls where built. Now, a second chance to relive the popular department where you can wear all the old goodies that you can.

Bring back the good old times

A buffet of the rare, beautiful and luxurious old fashioned clothes from various pop-up stores to vintage vendors. Here you can find Glorious Dias and The Vintage Junkie Manila with pop-up stores Luntian Palamuti Atbp, Wear Kahel, RioTaso, Season Pass and so much more where they help the fashionistas find the those old gorgeous clothes to re-wear them. This vintage community brings back the fashion era from the 1960.

The moment you stepped in you are greeted with an atmosphere from the past. A past that screams with a visual feast of all the vintage clothes with the background music of Manila in the 1960s to 1970s. A fashionista gets drowned with so much choices from clothes to accessories. A feeling of endless creativity and that fashion could never die.

A Fashionista’s dream come true

Jodinand Villaflores Aguillon advocate of upcycled fashion and the owner of Glorious Dias have dreamt of this event for a long time and it finally happened with The Vintage Junkie Manila, Season Pass, Hub Make Lab, Pineapple Lab and The First United Building. A moment where everyone can be on a one stop shop of all vintage as a new fashion or a restyled new trend. People in this event may be unaware that they are already creating an impact. A gesture to buy these old clothes as to repurpose or upcycled already help reduce textile waste that has become one of the major impact to the environment. At the same time, the consumers learned to appreciate these clothes, the people who made them and ourselves. The Second Chances brought such awareness and impact in this small community.

Create a habit of awareness

This one day event created an echo of meaningful gesture. A gesture would hopefully allow modern consumers to understand the value of clothes and the people behind it. An aim to help create a shopper’s habit to spend less and buy smartly on their next fashion items.

Fashion Revolution Week is our annual campaign bringing together the world’s largest fashion activism movement for seven days of action. It centres around the anniversary of the Rana Plaza factory collapse, which killed around 1,138 people and injured many more on 24 April 2013.

This year, as we marked the tenth anniversary of the Rana Plaza factory collapse, we remembered the victims, survivors and families affected by this preventable tragedy and continue to demand that no one dies for our fashion. To define the next decade of change, we translated our 10-point Manifesto into action for a safe, just and transparent global fashion industry. Our campaign platformed the work of our diverse Global Network who provided local interpretations of their chosen Manifesto point(s). We believe that while fashion has a colossal negative impact, it also has the power and the potential to be a force for change. Together, we expanded the horizons of what fashion could – and should – be.

Here, catch up on some of the week’s highlights and find out how to stay involved with our work, all year round.

Remembering Rana Plaza

Fashion Revolution Week happens every year in the week coinciding with April 24th, the anniversary of the Rana Plaza disaster. On April 24th 2013, the Rana Plaza factory building in Bangladesh collapsed in a preventable tragedy. More than 1,100 people died and another 2,500 were injured, making it the fourth largest industrial disaster in history. On April 24th, we paused all other campaigning to pay our respects to the victims, survivors and families affected by this tragedy, and came together as a global community to remember Rana Plaza.

As we reflect a decade on, we are inspired by and celebrate the progress made in the Bangladesh Ready-made Garment (RMG) sector by the Accord. The International Accord on Fire and Building Safety was the first legally-binding brand agreement on worker health and safety in the fashion industry and is the most important agreement to keep garment workers safe to date. This year, we pay tribute to the joint efforts of all Accord stakeholders who have significantly contributed to safer workplaces for over 2 million garment factory workers in Bangladesh, including the Bangladeshi trade unions representing garment workers, alongside Global Union Federations and labour rights groups. We welcome the introduction of the Pakistan Accord and would like to see the adoption and success of the International Accord replicated in all garment producing countries.

Manifesto for a Fashion Revolution

Our theme for Fashion Revolution Week 2023 was Manifesto for a Fashion Revolution. Back in 2018, we created a 10-point Manifesto that solidifies our vision to a global fashion industry that conserves and restores the environment and values people over growth and profit. This year we called on citizens, brands and makers alike to sign their name in support of turning these demands into a reality, boosting our signature count to 15,500 Fashion Revolutionaries and counting. We are immensely grateful to everyone who has and continues to sign; our power is in our number and each signature strengthens our collective call to revolutionise the fashion industry.

To campaign for systemic change in the fashion industry, we themed the week around complementary Manifesto points, providing ways to be curious, find out and do something daily around each of them. From supply chain transparency to living wages, textile waste to cultural appropriation, freedom of association to biodiversity, we shared global perspectives and solutions to fashion’s most pressing social and environmental problems.

Over the past ten years, the noise around sustainable fashion has only got louder. But meanwhile, real progress is too slow in the context of the climate crisis and rising social injustice. That’s why Fashion Revolution Week 2023 was an action-packed and future-focused campaign that amplified the actions and perspectives of Fashion Revolutionaries around the world.

View this post on Instagram

Global Conversations

To capture these global perspectives, we launched the Fashion Revolution Map on Earth Day, which coincided with the start of Fashion Revolution Week. Developed by Talk Climate Change, the Map served as a global forum to reflect on the week’s themes and events, using our Manifesto as a talking point. Fashion Revolutionaries continued the discussion offline by inviting their family, friends, colleagues and classmates to imagine what a clean, safe, fair, transparent and accountable fashion industry would look like with us. These conversations were then recorded on the Map as a source of inspiration and knowledge exchange.

Anyone can be a Fashion Revolutionary; it starts with a simple dialogue about the changes you want to see in the fashion industry. Make your voice heard by contributing to our map today and help change the fashion industry through the power of conversation!

View this post on Instagram

Good Clothes, Fair Pay Highlights

Ten years on from Rana Plaza, poverty wages remain endemic to the global garment industry. Most of the people who make our clothes still earn poverty wages while fashion brands continue to turn huge profits. At Fashion Revolution, we believe there is no sustainable fashion without fair pay which is why we launched Good Clothes, Fair Pay as part of a wider coalition last July. The Good Clothes Fair Pay campaign demands living wage legislation at EU level for garment workers worldwide, building on Manifesto points 1 and 2.

During Fashion Revolution Week, our EU teams coordinated awareness events, campaigns and marches to mobilise signatures for this campaign. On April 25th, we headed to the European Parliament with Fashion Revolution Belgium to demand better legislation in the fashion industry. The day of action consisted of a panel discussion between Members of the European Parliament and impacted fashion stakeholders, and ended with a stunt outside the Parliament. Fashionably Late highlighted that the EU is running out of time to act on poverty wages in fashion. This stunt was replicated by our teams in Germany, France and the Netherlands throughout Fashion Revolution Week to demonstrate EU-wide solidarity with the people who make our clothes.

We have less than three months left to collect 1 million signatures from EU citizens to push for legislation that requires companies to conduct living wage due diligence in their supply chains, irrespective of where their clothes are made. If you are an EU citizen, sign your name here. If you’re unable to sign, please support the campaign by sharing it far and wide online.

View this post on Instagram

Fashion Revolution Open Studios Highlights

Fashion Revolution Open Studios is Fashion Revolution’s showcasing and mentoring initiative since 2017. Through exhibitions, presentations, talks, and workshops with emerging designers, established trailblazers and major players, we celebrate the people, products and processes behind our clothes.

This Fashion Revolution Week, Fashion Revolution Open Studios joined forces with Small but Perfect to spotlight the work of 28 European SMEs taking part in their circularity accelerator project. Forming part of this European events programme, Fashion Revolution Open Studios held a two-day event in partnership with The Sustainable Angle and xyz.exchange at The Lab E20. The event showcased seven innovative designers from the Small But Perfect cohort of sustainable SMEs and displayed how they are embedding circular solutions into their work, from crafting grape leather handbags to developing community approaches to making and working together. Alongside the exhibition, there were livestreamed webinars, workshops and panel discussions to explore the projects and hear about some of the the challenges facing small businesses and the industry at large in switching to circular business models.

Global Network Highlights

With 75+ teams from all around the world, Fashion Revolution Week 2023 championed the perspectives and contributions of our Global Network. Here are just a small selection of highlights from our country teams:

Fashion Revolution New Zealand unpacked each Manifesto point with industry trailblazers in an Instagram Live series.

Fashion Revolution teams in Bangladesh and Sweden co-organised a virtual panel discussion on shifting consumer behaviour.

Fashion Revolution Singapore celebrated the launch of their digital zine MANIFESTO.

Fashion Revolution teams in Iran and Germany collaborated on Women, Life, Freedom, a joint exhibition.

Fashion Revolution Nigeria shared the stories and journeys of local slow fashion brands.

Fashion Revolution Argentina invited us to join their Wikipedia edit-a-thon.

Fashion Revolution teams in Vietnam, South Africa and Scotland hosted local community clothing swaps.

Fashion Revolution India won the Elle Sustainability Award for Eco-Innovation in Fashion.

Fashion Revolution Uganda brought together the country’s top designers and brands at Kwetu Kwanza.

Fashion Revolution teams in UAE and Canada both held local design competitions for students.

Fashion Revolution Hungary championed the revival of traditional folklore practices in clothing and fashion.

Fashion Revolution USA discussed the fashion industry’s impact on people and planet in a 2-part Zoom series.

Fashion Revolution Uruguay hosted Fashion Celebrates Life, a community picnic themed around Manifesto point 10.

Fashion Revolution teams in Chile and Portugal shared their Fashion Revolution Week highlights with us on Instagram Live.

You are Fashion Revolution

We are so grateful to everyone in our community for getting involved in Fashion Revolution Week on social media and beyond. Every single voice makes a difference in our fight for a fashion industry that conserves and restores the environment and values people over growth and profit.

While Fashion Revolution Week 2023 may be over, our community, our campaigning and our movement continues, 365 days a year. Please join us in fighting for systemic change by:

Following us on social media: Stay up-to-date by following us on Instagram, Facebook, Twitter, TikTok, LinkedIn and YouTube, and signing up to our weekly newsletter.

Finding your country team: Connect with the teams in your region by following them online, attending their events and volunteering with them. Find your country team here.

Using our online resources: Our website is a treasure trove of information, from how to guides and online courses to annual reporting on transparency on the fashion industry. Get started here.

From all of us in the Fashion Revolution team, we appreciate your support and we look forward to seeing you next year!

A ruhák javítása által spórolhatunk, miközben kreatív tevékenységet folytatunk, sőt, radikális lépést teszünk a tömeggyártás és a nem minőségi ruhakereskedelem korszakában a valóban fenntartható divat felé. Az alábbiakban a Nylon cikke nyomán hívjuk fel a figyelmet a ruhajavítás fontosságára, egyúttal felszólítjuk a fast fashion vállalatokat, hogy tegyenek ők is lépéseket ezzel kapcsolatban!

Lindsay Rose Medoff, a Suay Sew Shop ügyvezető igazgatója, ruhafelújító, a Los Angeles folyó egyik kanyarulatának mentén telepedett le. Elnézést kér, ha egy vérző szívű aktivistának tűnik; ez csak azért van, mert lelkesen elkötelezett aziránt, amit csinál. A Suay, mondja, több, mint egy címke vagy egy stílusos divatház. Ez nemcsak „egy közösségi újrafelhasználási kultúrát teremt”, hanem igyekszik szabványossá tenni a ruhák javítását. Miközben a fenntarthatóság a „tudatos fogyasztás” szlogent hangoztatva adja el termékeit, „számos módon elitista” eszközökkel, a ruhajavítás ősrégi művészete nem követel többet, mint a tű, cérna és akarat, véli Medoff. Amit ők csinálnak, az a ruhák élettartamának meghosszabbítására és a felesleges textilek hulladéklerakókon kívül tartására alkalmas módszer, egyúttal pedig a fenntarthatság elérhetővé tétele.

Az olyan eljárások, mint a stoppolás és a foltozás, valaha a háztartásbeliek vérében volt, mára azonban az eldobható divat áldozatává vált, hiszen olcsóbb cserélni, mint megjavítani. A vásárlók 60%-kal több ruhát vásárolnak és fele annyi ideig használják a megvett divatcikkeket, mint 15 évvel ezelőtt. Ennek eredményeképpen a textilhulladék problémája elburjánzott: csak 2018-ban az USA-ban mintegy 17 millió tonna ruhát, cipőt és háztartási textilhulladékot dobtak ki az amerikai Környezetvédelmi Hivatal szerint. Ez a mennyiségű hulladék több, mint 775 000 db Szabadság-szobrot tenne ki.

Medoff és csapata hetente több ezer font súlyú kiselejtezett textilt gyűjt össze újrafelhasználásra vagy újrahasznosításra. A ruhajavítás iránt jelentősen megnőtt az érdeklődés Amerikában, kiváltképpen pandémia alatt. Múlt év vége felé Medoff elhatározta, hogy a szombatok a Suaynál „Mentsd meg szombat”-ok lesznek. 10:30 és 15:30 között maszkos vásárlók formálnak sort törődést igénylő ruháikkal: lyukas pulóver, ruha elromlott cipzárral, farmernadrág szellősre kopott ágyékkal…

A Suay árai 10 és 40 dollár között vannak, a javításhoz szükséges idő szerint beárazva, illetve belefoglalva azt a pénzügyi alapot, mely támogatja a Los Angeles-i ruhaipari munkásokat, akik gyakran vannak túlterhelve és alulfizetve. Medoff 8 fős csapata többszáz ruhajavítást végez el minden héten és ez olykor megkétszereződik.

„Azt gondolom, hogy előbb-utóbb az emberek rájönnek majd, hogy nincs szükségük egy nagyvállalatra, aki a hősük lehet a fentarthatóságban; nem szükséges vásárolniuk egy újrahasznosított műanyagpalackokból készült dzsekit, hogy részt vehessenek a fenntarthatóság előre mozdításában. Saját maguk hősei lehetnek azzal, hogy megjavítják a saját cuccaikat.” – nyilatkozta.

A ruhajavtás/foltozás olyan régi, mint a ruha maga, mondja Kate Sekules divattörténész, ruhajavítást oktató tanár és a Mend! A Refashioning Manual and Manifesto könyv szerzője (nem került kiadásra magyar nyelven – a szerk). A legelső emberek állati bőrökből készült ruházatot viseltek; az ókori Egyiptomban 3-4-szer javították meg a textileket, mielőtt azt valaki sírjába tették balzsamozó rongyként; a EDO korszakban a japánok használták a „little stabs” hímzést, hogy megerősítsék a házilag szőtt textíliákat. (Sashiko a hímzés neve, nagyon látványos, viszonylag gyorsan, kevés varrástudással is elkészíthető, lsd. „little stabs” – a szerk.) A dolgozó emberek évszázadokon át rengeteg mindent kitaláltak, ami meghosszabbította a ruháik életét, hiszen a textilek „rendkívül értékesek voltak és érdemes volt azokat megőrizni” – egészíti ki Sekules.

Sekules szerint a fast fashion termékeket is megéri megjavítani, ha szükséges! „Még ha az a darab a fast fashion vagy big fashion rendszerekben készült, emberek gyártották és erre emlékeznünk kell!” – figyelmeztet Sekules. „Nem tiszteljük azokat az embereket, akiket a fast fashion rabszolgává tett – ‘rabszolgává tenni’ egy erős, de nem mindig pontatlan kifejezés.”

Sekules egyben a „látható javítás”-nak ismert technika indítványozója. Ahelyett, hogy a javításokat elfednénk, amennyire csak lehetséges, a látható javítás a rehabilitáció helyére irányítja a figyelmet – afféle fashion statementként vagy politikai akcióként. „Ez egy seb és jelvény egyszerre; megmutatod a világnak azon szándékod, hogy megőrizd, fejleszd és egyedivé tedd a dolgaidat, egyszerre.” – magyarázza. A #MendMarch hashteget találta ki az Instagramon e célból, amivel egyre növekvő közösséget formált. Az emberek valóban mögötte állnak a kezdeményezésnek, hiszen nemcsak praktikus, de végtelenül kreatív és bárki tudja művelni a saját, egyedi módján. „Nincsenek szabályok. Nincsen jó módszer. És nincsen rossz módszer sem.” – állítja Sekules. (@invisblemend az Instagramon – ha követni szeretnéd a mozgalmat.)

Történelmi tények bizonyítják, hogy a javítás a szűkösség és a hiány idején általában lendületet kap. A ruhák javítása egy meditatív élmény lehet, ami „elzárja az elmét” a stressztől, az idegeskedéstől és az unalomtól. És amikor benne vagyunk a ruhajavításban, észrevesszük, hogy „ma ruházkodásunkkal való kapcsolatunkra is ráfér a javítás.”

Orsola de Castro szerint, aki a Fashion Revolution globális kreatív igazgatója és a Loved Clothes Last: How the Joy of Rewearing and Repairing Your Clothes Can be a Radical Act könyv szerzője, az egymással való kapcsolatunknak is szüksége van foltozásra. „Nem bánunk egymással egyenlően,” mondja.

„Ha meg kellene győznünk a Z generációt a javítás hozzáadott értékéről, természetesen le kell lassítanunk a rendszert; azt kell mondanunk, hogy jobbat akarunk, nem többet,” vallja.

De Castro úgy hiszi, hogy a H&M-nek és Zarának is nagyobb felelőséget kellene vállalnia ruháik élettartamáért, a boltokban megfizethető áron elérhető javítás lehetőségét felkínálva. „Ez kellene legyen a modern visszavételi rendszer,” mondja. Már nem lenne szabad azt hangoztatni, hogy ’hozz be egy régi valamit és mi újra fogjuk hasznosítani akárhogyan, akármikor, de sose tudod meg, hogyan.’ Inkább így kellene a felhívásnak hangzania: ’hozz nekem valami szakadt, hibás holmit, és én meg fogom javítani.’”

Míg a körforgásos divat, amelynek nagy része a fiber-to-fiber újrahasznosítás innovációira összpontosít, nehezen értelmezhető az egyén számára, de Castro szerint a ruhák hosszabb forgalomban maradásának elősegítésért „mindannyian tehetünk”. A Waste & Resources Action Program szerint, ha csak három hónappal meghosszabbíthatjuk a ruhák élettartamát, az már 5–10%-os csökkenést eredményezhet a szén-, hulladék- és vízlábnyomokban.

„Vissza kell állítanunk a javítást kultúránk részévé” – zárja a gondolatmenetet Orsola De Castro.

Fordította: Sütő Annamária, forrás: Nylon.com, képek forrása: Nylon.com, Unsplash, Seamwork.com

El modelo de producción y consumo de la industria de la moda es responsable de que más de 900 mil toneladas de textil acaben en la basura cada año en España. Solo un 10% de este residuo llega a recuperarse, el resto se incinera provocando la emisión de gases contaminantes. Esto es consecuencia de la fast fashion, que ha provocado que al año se fabriquen 150.000 millones de prendas en todo el mundo y que compremos un 80% más de ropa que hace una década.

No hay mejor forma de gestionar el residuo que la prevención, en esta línea la frase de la fundadora de Fashion Revolution, Orsola de Castro, “La prenda más sostenible es la que ya tienes en el armario” refleja que la primera erre es la clave: reducir. Pero también otras erres son fundamentales, como Repensar (replantearnos a qué responden nuestras compras) y Reparar, el cuidado de nuestras prendas y sus arreglos son actos verdaderamente sostenibles.

Foto Altrapo Lab

La V edición del Maratón de reciclaje textil organizado por Altrapo Lab y La Casa Encendida, transformado a un formato virtual, ha tenido como objetivo impulsar la moda circular y acercarla al público de manera accesible y reivindicativa. Los días 13, 14 y 15 de noviembre de 2020 a través de los canales y redes sociales de las dos organizaciones quedó claro el mensaje: una moda con impacto positivo es posible y la prevención y sensibilización son fundamentales para conseguirlo.

Después de cuatro ediciones presenciales del Maratón generando en La Casa Encendida un espacio de encuentro con una atmósfera muy particular y plástica, esta edición online se presentaba como un reto. Pero también como una oportunidad de ganar alcance y profundidad en las propuestas con un programa que invitaba a la participación y a la reflexión.

En el centro de la programación, al igual que otros años, se ha desarrollado el espacio de creadoras. Una convocatoria dirigida a diseñadoras y estudiantes de moda que propone crear una prenda a partir de ropa en desuso en directo durante el evento. Este año, su proceso creativo se pudo seguir a través de entrevistas en Instagram live con los cinco proyectos seleccionados. Además de mostrar su proceso de creación, nos dieron a conocer las razones por las cuales trabajan en esta vertiente del diseño basado en la reutilización y los objetivos que hay detrás de sus prendas. Los cinco proyectos participantes fueron:

Lara Padilla, creadora multidisciplinar con una propuesta, La Sra.D, presenta un proyecto de moda Art Fashion que nace del proceso artesanal que comprende el diseño de la prenda, la confección y su acabado final a través de la pintura a mano.

Foto Altrapo Lab

Ayaloik, Sara Ayala y Andrea Loik, con un proyecto que pone en común el diseño zero-waste con las técnicas tradicionales japonesas de sashiko y boro, que se empleaban para parchear las prendas de algodón (boro) e unirlas con pequeñas puntadas.

Foto Altrapo Lab

Olmedam, Miguel Peñaranda, artista visual y diseñador de vestuario, con su proyecto Crítica de lo invisible – Los ojos que ya ven– se inspira en los plumíferos que tan de moda están desde hace unos años, utilizando ropa de desecho triturada para rellenar dicha prenda.

Ana Almenara, diseñadora de moda que finalizó su proyecto fin de carrera en la London College of Fashion con un estudio sobre la customización de ropa titulado “la customización como búsqueda de identidad del sujeto”.

Homesickness, Manuel Sánchez, Ana M.García, Magdalena Rodriguez y Daniel Mirás, estudiantes de gestión industrial de moda en la Universidad de la Coruña. Con su proyecto buscan generar un impacto positivo a través del diseño de un chubasquero confeccionado con tienda de campaña y con un compartimento trasero para recoger residuos encontrados en cualquier espacio natural.

El viernes 13 se inauguraba esta quinta edición con una entrevista a Orsola de Castro, diseñadora pionera en upcycling, líder de opinión en moda sostenible y co-fundadora de Fashion Revolution, una organización global con participación en más de 100 países alrededor del mundo que lucha por conseguir una moda transparente y sostenible. (250 visualizaciones)

Después de 4 años de evento nos parecía fundamental hablar sobre Cómo nuestra ropa se convierte en residuo a través de una mesa redonda con personas expertas. Analizando tres aspectos; cómo se ha acelerado la industria y nuestro consumo de moda en los últimos años, cómo se gestiona el residuo textil post-consumo y cómo podemos prevenir y reducir los efectos de la fast fashion. Para ello, el sábado por la tarde charlamos con Brenda Chávez, periodista e investigadora especializada en consumo, Cristina Salvador, fundadora y responsable de Recumadrid, entidad dedicada a la recogida de textil y Jessica Checa, miembro de Fashion Revolution Spain. (300 visualizaciones)

Durante el evento se realizaron dos talleres online de upcycling. Uno dedicado a confeccionar un bolso a partir de patrones y con tejidos en desuso. Y otro que planteaba tres enfoques diferentes de diseño de camisetas a través de tres técnicas de upcycling. Dentro de estas actividades que invitaban a la participación, también se realizó un Unescape Room, un juego de lógica con el reto de decodificar el sistema de la moda. Más de 400 personas siguieron estas actividades desde sus casas.

El domingo se cerraba esta edición del Maratón con los cinco proyectos protagonistas presentando sus prendas finales. Una oportunidad de expresar la importancia de las alternativas en diseño de moda, donde la reutilización otorga mayor valor a la prenda y transmite un mensaje de concienciación y sostenibilidad. Habiendo alcanzado en los directos realizados unas 12400 visualizaciones, se finalizó así esta edición con la sensación de haber cumplido las expectativas de una formato completamente nuevo. La creatividad, la experimentación y la participación han sido los principales motores de este encuentro que ha sido posible gracias a un firme compromiso con las iniciativas que impulsan la moda circular y el consumo transformador de ropa.

Azon gondolkozol, hogy miért is kellene foglalkoznod a 2021-es fenntartható divattrendekkel, amikor még hónapokig be leszünk zárva a járványhelyzet miatt? Jogos a kérdés, mivel valószínűleg napok óta te sem viseltél mást, mint pizsamát, melegítőt és papucsot. De ne csüggedj, hiszen sok vidám és fenntartható körülmények között készült ruhadarab vár arra, hogy feldobja a kedved és kizökkentsen ebből a helyzetből!

Lássuk a 2021-es fenntartható divattrendeket!

Patchwork

A patchwork a 70-es években volt divatos, de idén is virágkorát fogja élni! Mindenhol és mindenben megtalálható lesz, a ruháktól és a farmerektől át a táskákig, sőt a cipőkig is. A várakozásoknak megfelelően ezt a trendet főleg farmereken keresztül fogjuk látni, de lehet akár más hulladék szövetekkel is kombinálni, beleértve mindent a bőrtől a csipkéig. Akár merész, akár visszafogott a stílusod, a lehetőségeknek csak a képzelet és az egyéni stílus szabat határt!

Élénk színek

Ha azt hitted, hogy a neonárnyalatok csak a múló 90-es évek divatjára jellemzőej, akkor tévedtél, mert igenis visszatértek! Legyen szó monokróm vagy polikróm mintákról, ez az év az élénk árnyalatok berobbanását hozza magával. Úgyis nagy szükség volt mindannyiunk felvidítására, nem igaz?

Újrahasznosított kötött darabok

Ez a trend már 2020 őszén megjelent, az újrahasznosított gyapjú növekedése jellemző a kötöttárú piacon. Puhább, így kellemesebb viselni, és az anyag beszerzéséhez alkalmazott gyakorlatok is humánusabbak. Manapság rengeteg márka használja ezeket a szálakat ruhadarabjai készítéséhez,mi pedig csak öröülni tudunk ennek! Viselj hozzá ékszereket és egy magassarkút, és már kész is vagy az esti programodra! Párosíthatod etikus, újrahasznosított kötött leggingssel is, ha lezser szeretnél lenni. Akárhogy is, készülj fel egy hangulatos, meleg és etikus ölelésre a pulcsidtól!

Hangsúlyos vállak

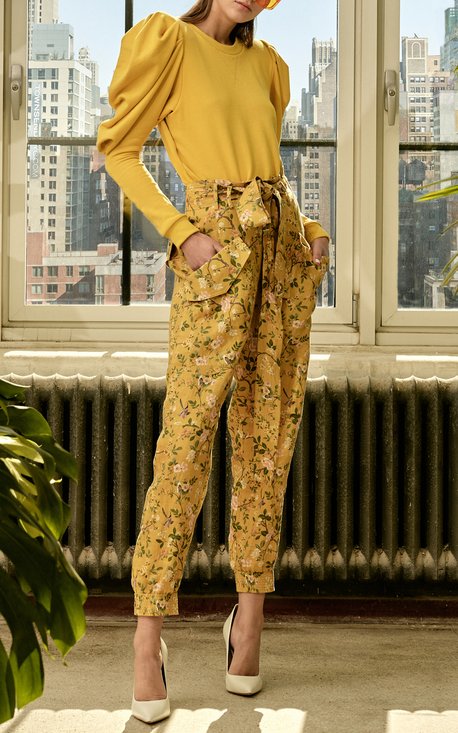

Akik a 80-as és 90-es években nőttek fel, jól ismerik az évtized egyik legforróbb divatját: a minél szélesebb vállakat! A válltömés és az erős vállak trendje sokféle formát ölthet: túlméretezett vállvédő fiúkabátok, háromszög alakú formák vagy eltúlzott puffos ujjak. S hogy mivel tedd még izgalmasabbá? Egy nagy öv a derekad kiemelésére vagy egy szűk, testhezálló nadrág igazi fordított háromszög alakot kölcsönöz az alakodnak!

Kaktuszbőr

Igen, tudjuk, a vegán bőr nem tökéletes… Gyakran olyan természetes szálakból készül, amelyhez rengeteg műanyag keveredik. De a kaktuszbőr más, hiszen ezek a szálak olyan erősek, hogy alig van szükségük polimerekre. A kaktuszbőr rendkívül erős, így az ebből készült kiegészítők még a legkeményebb, legnedvesebb körülmények között is hordhatóak.

Luxus sportruházat

A luxus sportruházat is új lendületet kap idén: laza, kézműves eljárásokkal készült pulóverek és sportos blézerek, jól kombinálható, kényelmes darabok révén válik izgalmassá 2021-ben ez a trend. Ne feledd, a sportruházat a legkönnyebben viselhető vonal, szuperül fel lehet dobni a szetteket egy-egy különleges ékszerrel, kiegészítővel.

Gyönyörű ruhaujjak

Nem elhanyagolható tényező a ruhaujjak kérdésköre, mivel az egész sziluettet befolyásolhatja az ujjak hosszúsága, szélessége, továbbá az, hogy puffos-e vagy testre simuló stb. Mondhatni, hogy ez a trend bizonyos mértékig a Zoom konferenciák közvetlen következménye, ahol testünk felső része a főszereplő, és ahol a testbeszéd a kezekre, karokra összpontosul. Mivel az ujjak valóban ellopják a showt, az alsórészt érdemes finomabbra hangolni – csak semmi túlzás! Párosíts egy drámai blúzt például farmerrel vagy sima szoknyával, a lehengerlő hatás nem marad el.

70-es évek ihlette farmer

Magas derék, bootcut fazon – örök klasszikus. Ezek a 70-es évek ihlette farmerek hízelegnek a női test formájának, időtlen varázst nyújtva e casual ruhadarabbal. Érdemes megismerni azokat a márkákat, amelyek környezetbarát farmert gyártanak és olyan szövetekkel dolgoznak, például a kender vagy a tencel.

Apró virágminták

Az apró virágminták az egyik kedvenc 2021-es divattrendünk. Számos kollekcióban felbukkantak ezek a természet isnpirálta printek. Keress túlméretezett ruhákat vagy viktoriánus stílusú blúzokat apró virágos nyomatokkal! A ruhát párosíthatod térdig érő csizmával, a blúzt pedig a 70-es évek ihlette farmerrel.

3D nyomtatott ruhák és kiegészítők

A 3D nyomtatott ruhadarabok nem annyira terjedtek el még, mivel a technológia igen drága. A Nike és az Adidas használja már a 3D technikát, a couture-ben pedig Iris van Herpen neve már több éve használja. Ez a trend jelenleg inkább kiegészítők, például cipők és táskák formájában van jelen elérhető árakon.

Batikolás

Már a tavalyi évben is nagyot mentek a batikolt darabok, de mostanában még inkább növekszik rájuk a kereslet. Vidámak, színesek, szóval nem lehet őket nem imádni. Jól mutatnak vegán edzőcipőkkel, egyszínű nadrágokkal és szoknyákkal.

Pufi dzsekik

Mivel az emberek egyre inkább a szabadban akarnak lenni, várható volt, hogy előtérbe kerülnek a praktikus és trendi pufi dzsekik a hideg beálltával. Fontos azonban megvizsgálni a vásárlás előtt, hogy mennyire fenntartható a kiszemelt kabát. Elegáns szettekhez és sportos lookokhoz is tökéletesen passzol, így érdemes befektetni egy trendi, ökotudatos darabba.

Szerző: Pölz Klaudia, forrás: eluxemagazine.com